STRUT CHANNEL ROLL FORMING MACHINE - ZTRFM

Zhongtuo unistrut channel roll forming machine

Strut channel roll forming machine

Uni Strut Channel Roll Forming Machine

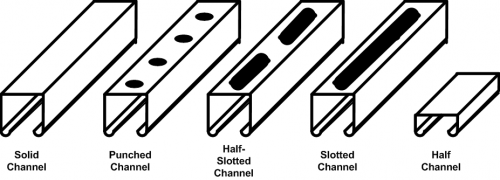

What’s Uni Strut Channel?

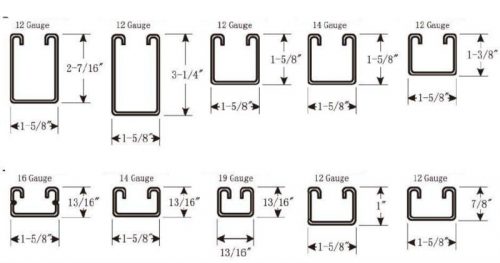

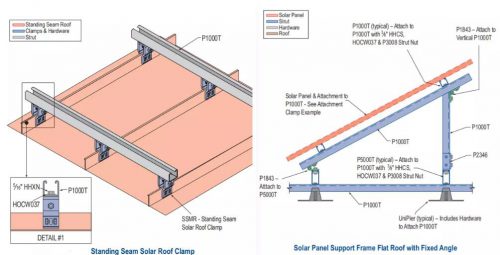

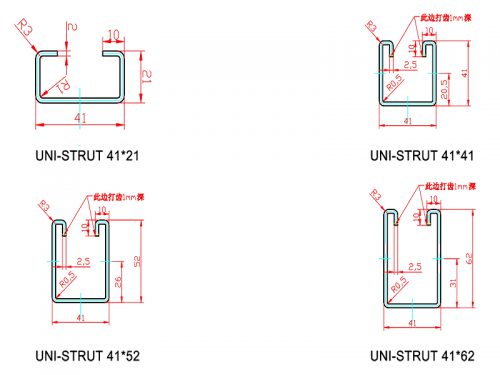

Strut Channel is a standard cold roll formed steel used in electrical industry or constructions for structural support. Which is usually formed from metal coil strips, roll formed into an open channel section with lips to provide additional stiffness. The basis strut channel sizes are: 41*41. 21*21, and also some customized shapes.

Strut Channel Roll Forming Machine is to form 1.5mm-3.0mm strut channels with various types. The machine is able to produce 3 or more types of strut channel by adjust the roll forming mould. We have 2 design of the adjust method:

Adjust the spacers to achieve the type changing. The workers need adjust all the spaces of top and bottom rollers. the change over time is at least 6-8 hours.

Replace the whole roll forming mill. The roll forming mill will fastened on a mill base, and easy to replace. The changeover time is within 2 hour.

Punch Holes Types of Strut Channel Roll Forming Machine

Hydraulic Presses

An economical solution for punching holes, the speed is only 3-5m/min even though we use big pumps. It is easy to change the punch mould to change the holes punched. Sometimes we will choose the hydraulic station with storaging device to enlarge the speed of the punching.

Rotary Punching

Rotary devices usually consist of two working rolls. It is difficult to synchronize the surface speed of the rotary device with the speed of the roll forming mill. Therefore, in almost all cases, the rolls are rotated by the strip, which is pulled by the roll forming mill.

The advantages of the rotary devices are that they are considerably less expensive than the presses, they can run at any roll forming speed, and can repeatedly produce the same pattern within tight tolerances. The speed can be up to 30m/min

The disadvantage of the rotary punch devices are the holes position is fixed, only to change the rollers to change the holes.

Mechanical Punch Press

Presently, We always suggest buyers to use punch press for holes punch if the holes and its position is various. The speed of the punching is at least 20m/min which is based on the capacity of the press. The punch press alway work with a servo feed for punching precision holes position.

- Feeding Type: Servo Motor Feeding

- Width of The Material: 0-200 mm

- Thickness of The Material: 0-3.2mm

- Feeding Motor Power: 1.3KW

- Max Feeding Speed: 200m/min

- Punch Press Capacity: 110 Ton

- Stroke Per Minute: 60-90 S.P.M, and 50 S.P.M fixed

- Stroke: 80mm

- Die Height: 410mm

- Slide Adjustment: 80mm

- Main Motor: 11KW*4

- Bolster Area: 1150-600-110

- Die Cushion Capacity: 6.3 Ton

- Die Cushion Stroke: 80mm

- Adopt limit switch to ensure the speed of uncoiler and leveler will be synchronous with the strut channel roll forming mill

Uncoiler and Leveler

- Adopt limit switch to ensure the speed of uncoiler and leveler will be synchronous with the strut channel roll forming mill and punch press.

- Capacity: 3 Ton

- Inner Diameter of the coil: 500-600mm

- Outer Diameter of the coil: 1500mm

- Motor Power: 2.2 KW

- Leveler Motor Power: 3 KW

- Leveling Rollers: 9, 4 for upper and 5 for bottom

- Adopt one body for uncoiler and leveler to save the space of the factory

- Total speed can be up to 20m/min

Roll Forming Mill

- Adopt H steel welded as the mill baseof the roll forming machine for strut channel

- Quality Iron Cast and theroll forming stand

- Roll Stands: 20 Groups

- Rolls Material: GCR15, quenched and tempered. HRC 58-62 °

- Shaft Material: ASTM 1045, 75mm diameter

- Motor Power: 45KW

- Gear Box transmission ( Know more about Roll Forming Transmission)

- All the driven part will be covered with safety guard

- Strut Channel Roll Forming Line Speed: 40m/min