STORAGE RACK ROLL FORMING MACHINE - ZTRFM

Zhongtuo upright rack roll forming machine

Storage rack roll forming machine

Upright Rack Roll Forming Machine

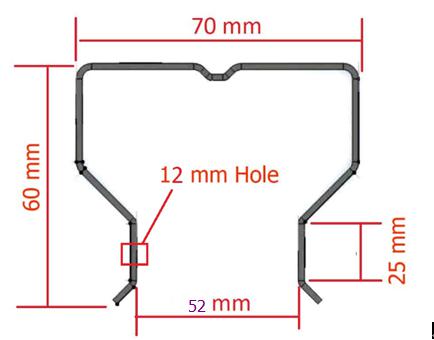

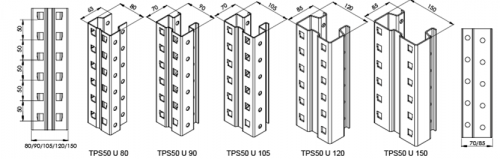

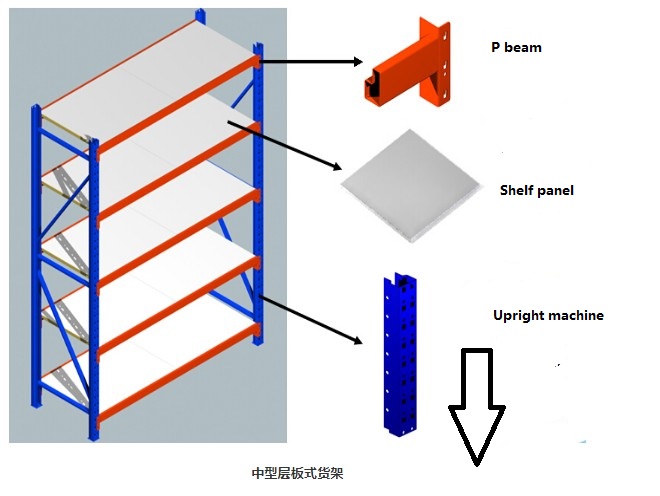

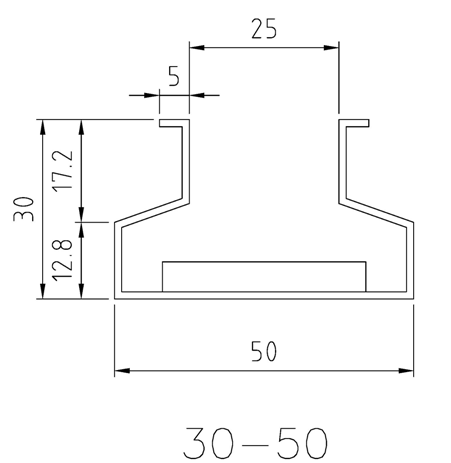

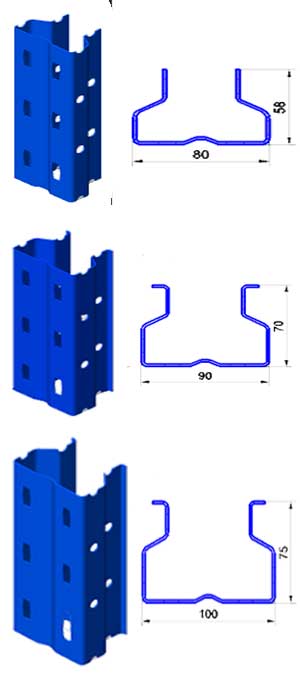

Introduction of Upright Rack

Upright Rack(also called Uprights or Upright Columns) vary in size and design depend on the load capacity and styles. Such as L Shape ( Light Capacity), C Shape (Medium Capacity), Special C Type for heavy Capacity. Holes(Tear Drop Design) and slots are punched during producing so that the load beams can be mounted into the Upright Racks. The heavy Upright Racks thickness up to 2.5mm.

The different sizes of the upright racks can be produced in one roll forming machine with holes and slot punched.

The Layout of Upright Rack Roll Forming Machine

Uncoiling–Punching Holes and Slots– Feeding and Guiding– Roll Forming– Cutting Off— Collecting.

M/C of Upright Rack Roll Forming Machine

- Uncoiler, 3 Ton Capacity, Manual or Automatic.

- Leveler as an option.

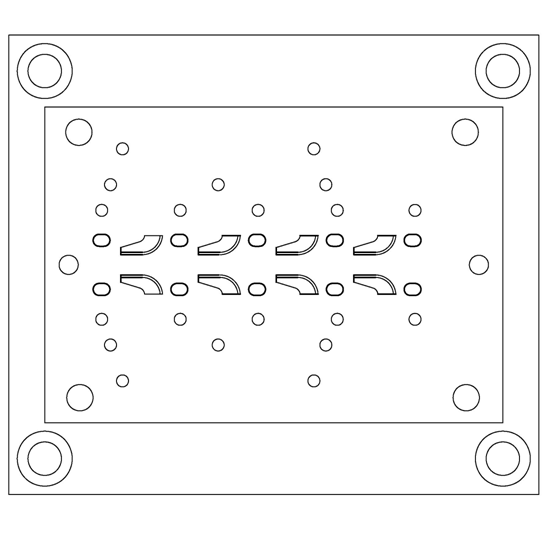

- Power Punch Press or Punch Holes Device

- Roll Forming Mill

- Cutoff Device

- Collection Table

- Controlled System

- Hydraulic Station

Specifications of Upright Rack Roll Forming Machine

The uncoiler is for uncoiling the coil strips, which is passive

Uncoiler

- 3 T Manual Uncoiler

- Coil Inner Diameter: 400-530mm

- Coil Outer Diameter: max 1500mm

- Loading Weight: 3T

- Uncoiling width: max 500mm

- Passive uncoiling and manual loosen and tension

Leveling machine

Leveling Machine us for leveling the strips be flatten before punching holes and roll forming.

- Adjustable type Feeding: right and left, to feed the strips into a right position

- Leveling type: upper 3 rollers, bottom 4 rollers

- Leveling motor power: 3KW

Servo feeding and punching

The feeder and punch press us for punching the presion hole in a right position and fastly

- Feeding type: Servo feeding

- Width of the material: 0-200mm

- Thickness of the material: 0-3.2mm

- Feeding Power: 3KW

- Feeding line height: 70-140mm

- Max line speed: 200m/min

- Model: C1N-110

- Capacity: 110 Ton

- Stroke per minute : 60-90 s.p.m, and 50 s.p.m fixed

- Stroke: 80

- Die height: 410mm

- Slide adjustment: 80mm

- Main motor: 11*4( the punch press supplier offered)

- Bolster area: 1150mm*600*110

- Die cushion capacity: 6.3 Ton

- Die cushion Stroke: 80mm

Roll Forming Machine

- Rolling Stations:16 stations

- Forming Speed: Approx. 10-15m/min.

- Diameter of Shaft: 70mm

- Material of Shaft: 45# steel

- Material of Roller: GCR15 overquenching HRC58-62 and chroming of 0.05mm thickness

- Transmission: By chain

- Motor Power:15KW

- Turkey Head: To Ensure the product be straight

Hydraulic Cutting Device

The Cut off unit is for cutting the racks into desired length

- Material of Cutting Mold: Cr12Mov with quenched treatment HRC 60-62

- Cutting Length and Quantity: Clients can set the length and quantity on the PLC touch screen

- Hydraulic Station Power:11KW

- Tolerance of Cutting Length: +/-2mm

The worker can set all the data of length, quantity, holes position on the touch screen which will control the machine

Control System

- The worker input the length and quantity of the product through touch screen, the touch screen will show the working status of the machine.

- Automatic stopping of the equipment after finishing setted producing.

- Operating System Language: English and Chinese

- Cutting length inaccuracy can be amended e

- control Panel: Button-type switch and touch screen

- Unit Of Length: Millimeter (mm)

- PLC Brand: Panasonic PLC

- Encoder: Omron Brand

- Frequency Converter Brand: Yaskawa

- Touch Screen: MCSG

- Controlled System Power: Overload Protection

- Voltage and Current: 415V, 50Hz, 3Phase