SANDWICH PANEL ROLL FORMING MACHINE - ZTRFM

Zhongtuo sandwich panel roll forming machine

Sandwich panels roll forming machine

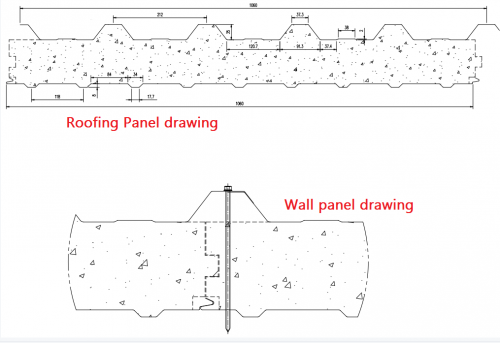

Sandwich Panels half automatic rolling machine down layer or for wall panel rolling machine is designed to make the sandwich panel sheets in a separated methods. Different with the fully automatic sandwich panel machine, by this type machine, you need, to make the down panel first and then upper layer machine. Meranwhile it needs another machine to press them together.

Advantage of this half automatic sandwich panel machines:

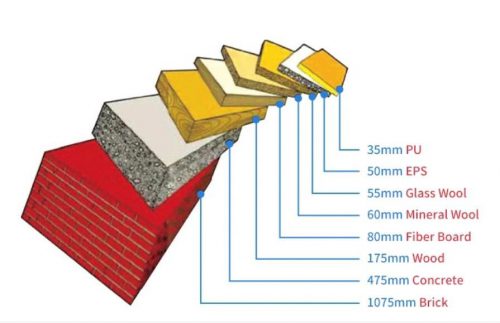

It can either be used to make the EPS sandwich panels, PU sandwich panel and others: EPS Sandwich Roof Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density EPS foam. Thanks to their properties the panels may be applied in object that require very high fire resistance, EPS sandwich panel is the most effective acoustic materials used on construction.

Discontinuous PU sandwich panel machine

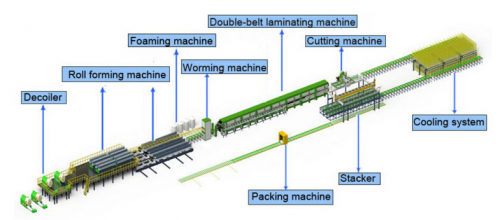

Fully Automatic Sandwich panel making machine, wall and roof panel roll forming machine line, Discontinuous PU sandwich panel machine allows you to make sandwich panel in batch and fully automatic.

It-has-including unwinding, before cutting, film, beading / molding, rock wool and spray delivery,Edge foam, continuous curing, cutting and other functions, high degree of automation, stable performance.Edge polyurethane foam systems, automatic feeding system, to ensure that the raw material requirements in full accordance with the ratio of mixing, spray evenly; using a reliable foam technology to ensure uniform sheet foam, dense, sheet closely connected.The production line is equipped with automaticcontrol system, userfriendly interface for easy operation, monitoring, advanced computer control, easy to adjust the entire line of argument, effectively ensure the production line stable and efficient operation.

Sandwich Panel for EPS, PU and rockwood making machine production Process:

(The upper)Dncoiler —Cutting —Film—Beading—Roll forming \ (Lower part)Uncoiler — Cutting →Film→Beading→Roll forming /—Rock wool delivery—Glue—Sealing side foam— laminating machine with Foam,Solidify,Roll forming—Cutting —Run-out table

Fully Automatic Sandwich Panel for EPS, PU and rockwood making machine

Main parameters:

Speed: 0~8m/min, frequency control.

Total power: about 200 KW

Production line length: more than 100 m

Workshop required: about 120m x 18mx 5.5m

PU injection machine: two or four components, original from Italy

Double belt length: 24m or tailor-made