HORIZONTAL WAVE ROOF SHEET MACHINE - ZTRFM

Zhongtuo horizontal wave roof sheet machine

Based on this need,barrel corrugated sheet rolling machine is developed based on the needs that thin sheet cannot be made to roof sheet by traditional roll forming machine. It can process material thickness from 0.15 to 0.30 mm and the roofing sheet length could be customized according to customer’s personal requirement. But limited by roll forming method, this machine needs to feed sheet and receive sheet by manual ZIRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience,capabilities. innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

When you need horizontally roll forming machine?

When need to make round wave roofing sheet roll forming machine.

When the material thickness between 0.13 to 0.25mm.

It allows you to make three or four pieces sheet roll forming machine together.

Horizontal round wave machine basic parameters

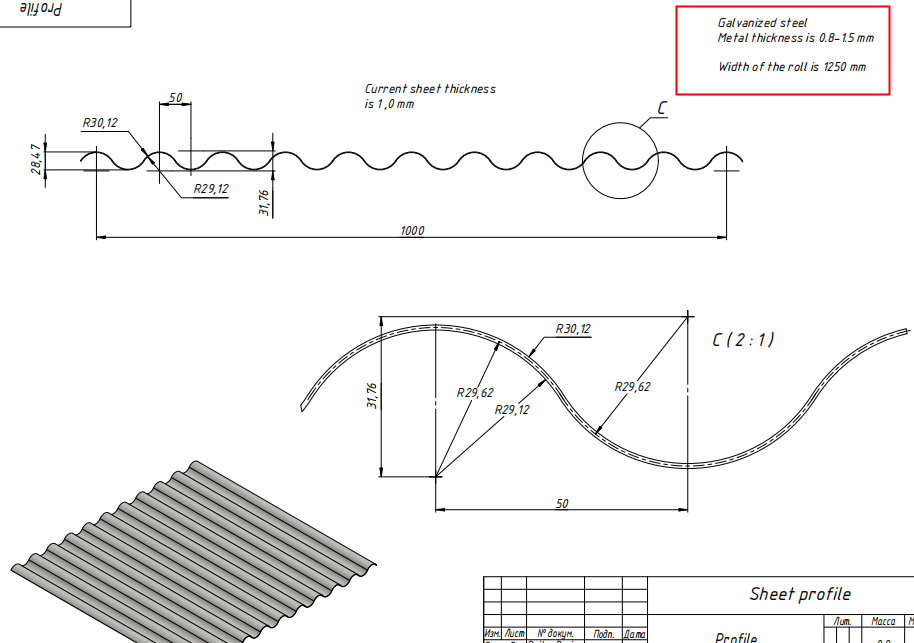

1. Feeding width: ≤1250 mm and it also adjustable.

2. Length: can be customized. The width could be 3 meters, 4 meter or 6 meters

3. Thickness: 0.13-0.5 mm, please specify the material nature like SG550 full hard, or normal one.

4. Speed: 10-15 pieces/minute

5. Shaft diameter: 450 mm

6. Power: 7.5 KW

7. The movable range of the feeding platform: 750-1200 mm

8. Control method: electric control box, forward and reverse rotation, speed regulation

For different thickness, it is easy to adjust, we adopt turbocharger adjustment method, only need to adjust one side; Other, they use the normal handrail, acuracy and effectiveness will be lower.

Work Flow:

Using this type horizontal round wave making machine, first you need to cut the long coil into pieces, which the length is specified what you need. And then feeding coil to machine by pieces.

Common problem when using Horizontal round wave machine

1. The R angle is too small, and the arc feels shocking and unsightly

2. The wave crest is not right, and the arc length on both sides is different

3. Edge rebound The smaller the side, the harder it is to press, the thinner the harder it is.

How we solve it?

1. Enchance the shaft process hardness and accuracy.

2. Carefully processing gear.

3. Meanwhile if you like,we can also use the gearbox as transmission method, but price will be a little higher.