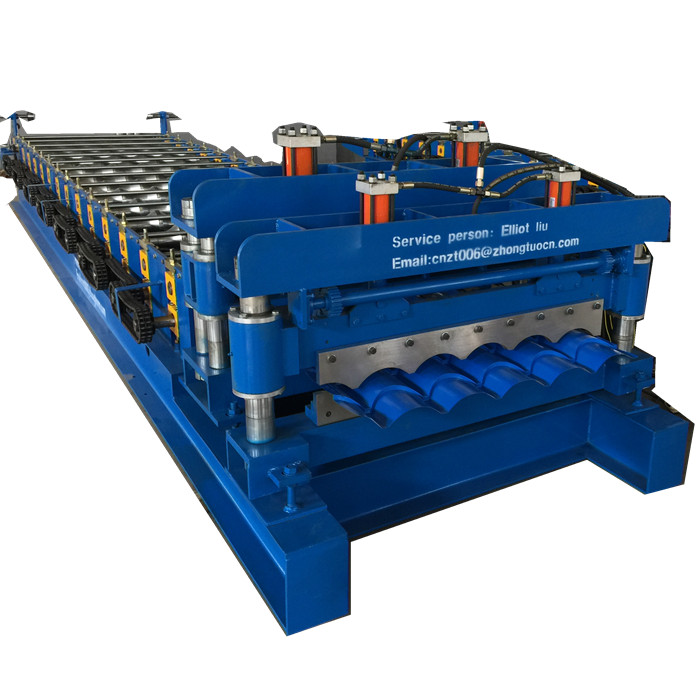

GLAZED TILE ROOFING SHEET MACHINE - ZTRFM

Zhongtuo glazed tile roofing sheet machine

Step tile roll forming machine

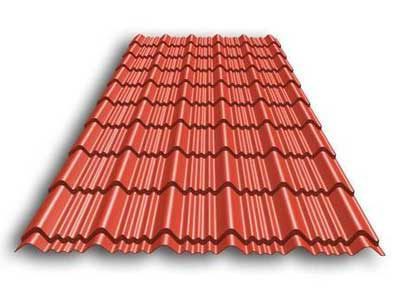

Glazed Steel Tile Making Machinery for Colored Glazed Steel Roofing Sheet is used to make the color glazed tiles in batch by the Steel Tile Making Machinery. the finished product of Glazed Steel Tile Making Machinery For Colored Glazed Steel Roofing Sheet is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste. This machine working speed is around 4-5 meter per minutes.

The types of glazed tile roll forming machine

Step Tile Roofing Sheet Making Machine

Metal roof tiles are most notable for their toughness and being virtually maintenance-free. This is due to them offering longevity in all climates and, on some tiles, featuring special finishes to prevent the build-up of mold and moss. This means that your roof can look incredible for decades to come without any ongoing cost. A metal roofing is lighter than a concrete or clay tile roof, more durable than an asphalt shingle roof, and easier to handle than long-run corrugate sheets.

It is the best reliable and affordable roofing system in the market place in a range of design and styles. Metal roofs can now mimic other roofing materials such as wood shake, asphalt shingles, and slate, however, the metallic look often compromises the authenticity of these renditions and the overall design.

Long Span Metal Sheet Roll Forming Machine

We offering you an outstanding quality range of, glazed tile making machine. These Long Span Metal Sheet Roll Forming Machine can be customized as per customer requirement based. as a result, These High-Speed roof tile machines for sale are Mostly known for its stability and superiority. Our roofing machines can be availed at the best competitive rates. Long span Roofing sheet and Wall Cladding give excellent stability in any weather.

Interlock roof panel roll forming machine

Interlock Roofing is a highly durable roofing product available in a range of different colors. also, Interlock Metal Roofing is lightweight, strong, and lasts long. It is also very cost-effective being that it is virtually maintenance-free, convenient, and easy to install.

Main Roll Forming Machine:

Driving Type: Chain(common) or Gear or Gearbox;

Forming Model: Integral Forming or Split Forming;

Forming Machine structure: Medium-plate Type(common) or Arch Type or Guide-pillar type;

Roller: 45# or Cr12 or GCr15 or GCr12MoV

Shaft: 45# or 40Cr; 70mm/80mm/90mm(common) or as design;

Motor Power: 4.0kW or 5.5kW or according to the design requirements;

Main Frame: 350# or 400# H-beam steel welded.