CORRUGATED ROOFING SHEET MACHINE - ZTRFM

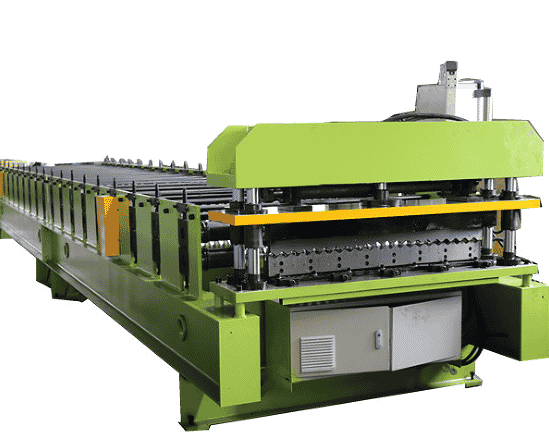

Zhongtuo corrugated roofing sheet machine

High speed corrugated roofing sheet machine

The metal corrugated roof is widely used for commercial and residential metal buildings, associated with residential and commercial. Corrugated Sheet Roll Forming Machine could be customized designed for its production.

Main Character of Corrugated Sheet Roll Forming Machine

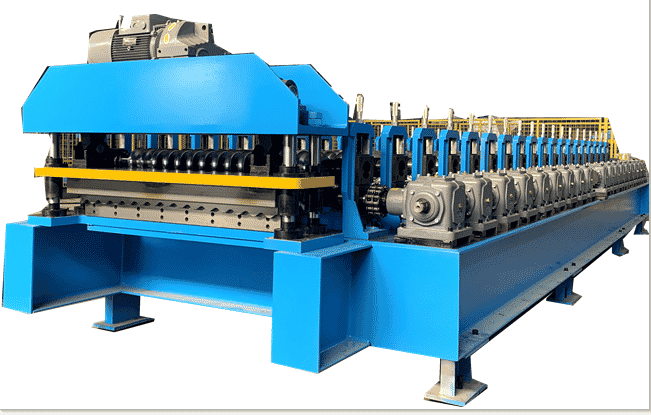

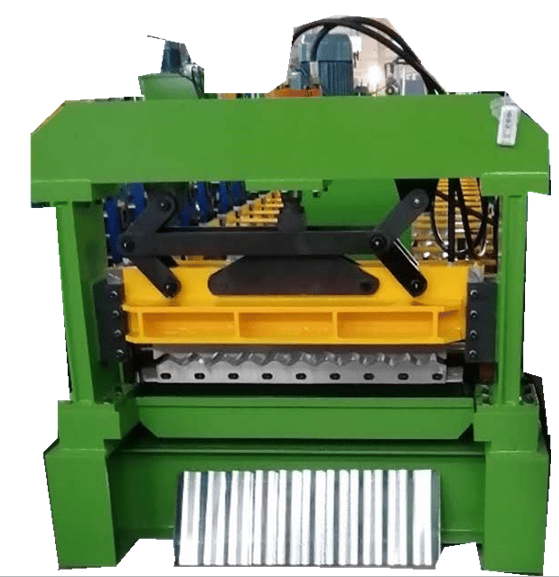

- Simple structure, good appearance since the whole machine is used profiled steel structure and wholly manufacturing after welding, in order to make it running stable and reliable.

- Completely automatic cutting, accurate length, and position trim cutting for the rear of profile sheets, no deformation.

- Easy installation, good performance for manufacturing in the factory.

- Low noise, high efficiency.

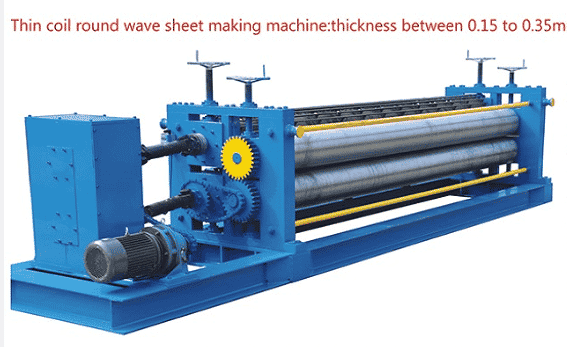

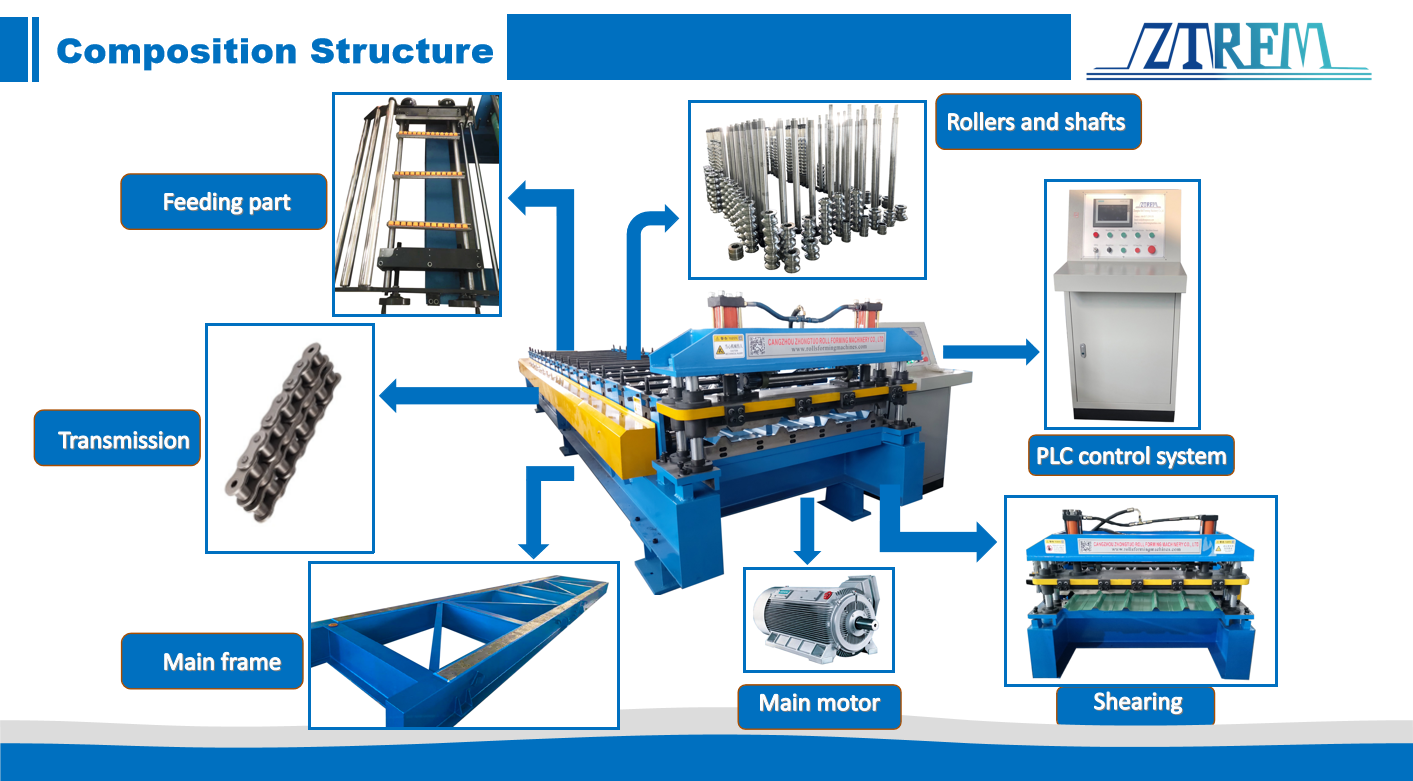

Structure of Corrugated Sheet Roll Forming Machine

This corrugated roll forming machine consists of 10 tons automatic decoiler, chain driven transmission, cassette type roller stations, mainframe (including guiding platform), hydraulic cutting device, hydraulic system, electric controlling system and auto stacker.

Working Flow of Corrugated Sheet Roll Forming Machine

Coiler loading → feed-in (sheet metal is put by guiding platform) → roll&forming → hydraulic cutting → auto stacker

Please click above pictures to choose check more types

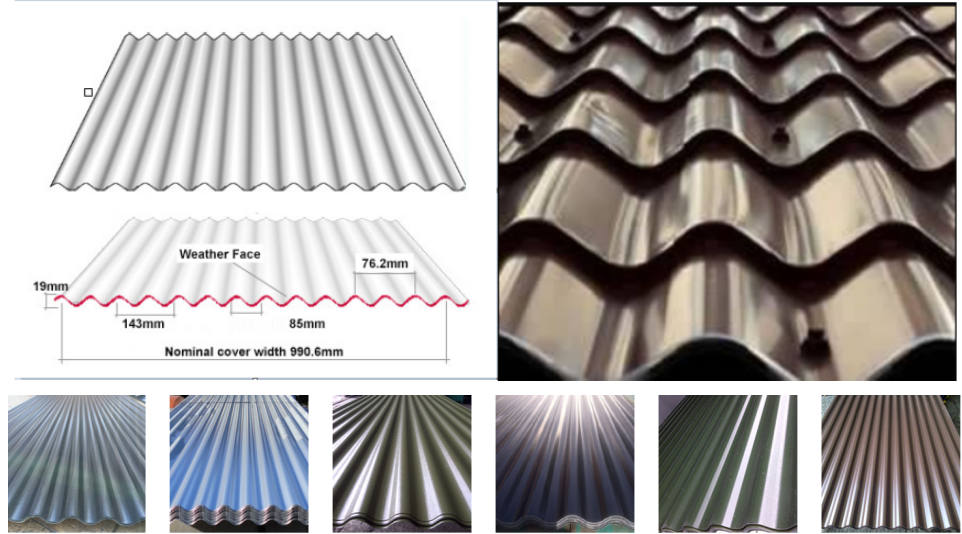

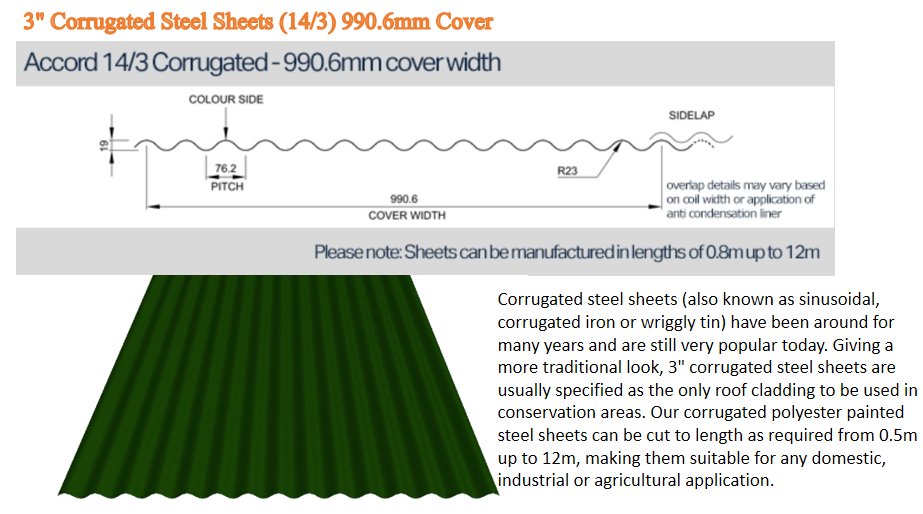

Corrugated metal roofing sheet and drawing profiles for your reference:

Corrugated Metal Panels

Normally corrugated panels are made of rippled metal sheets, one of the most commonly used panels in the industry. Corrugated sheet metal is a tough material, light weight, weather resistant, and practical for many different uses.

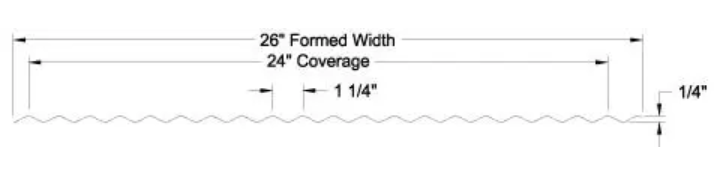

The 1-1/4″ corrugated metal panels primarily come in a galvanized finish and in lighter gauges (26-28-29 gauge). This panel has the slightest of the corrugated profiles making it great for use in both decorative and industrial applications. We can make this panel profile in just about any material you wish.

1-1/4″ x 1/4″ Corrugated Metal Panel

Steel corrugated roofing sheet rolling machine Elements

Same like other rolling forming machines, it is also composed by the following elements: Decoiling→guide&manual pre-cutter→roll forming→cutting→run out table

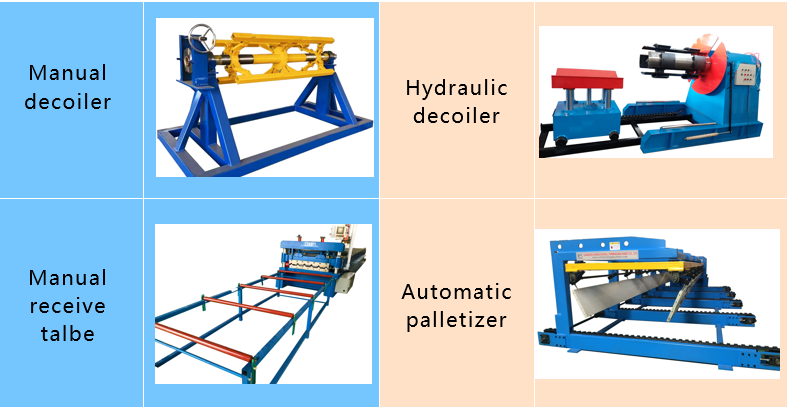

As to the decoiler, you can choose the manual one or the hydraulic one. As to the stacker, you can choose to use the manual one or the fully automatic stacker.

Here are more videos for your reference: