Oval pipe rolling forming machine - ZTRFM

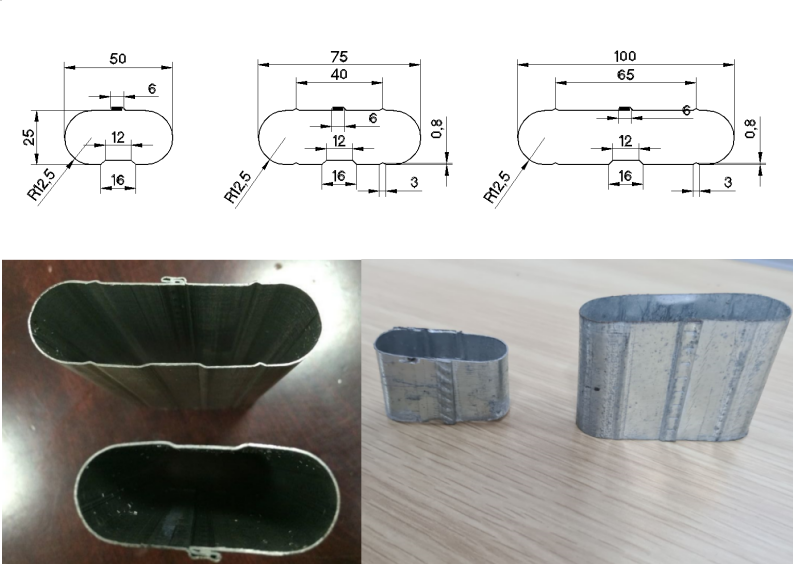

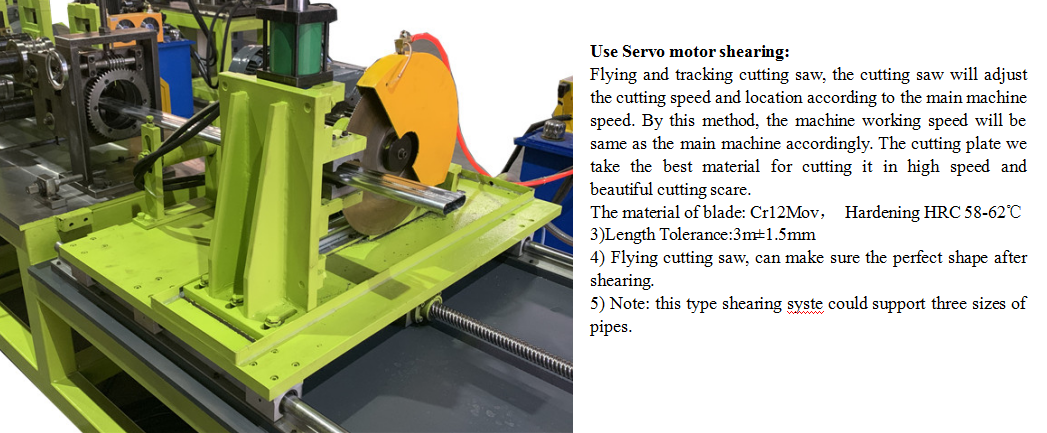

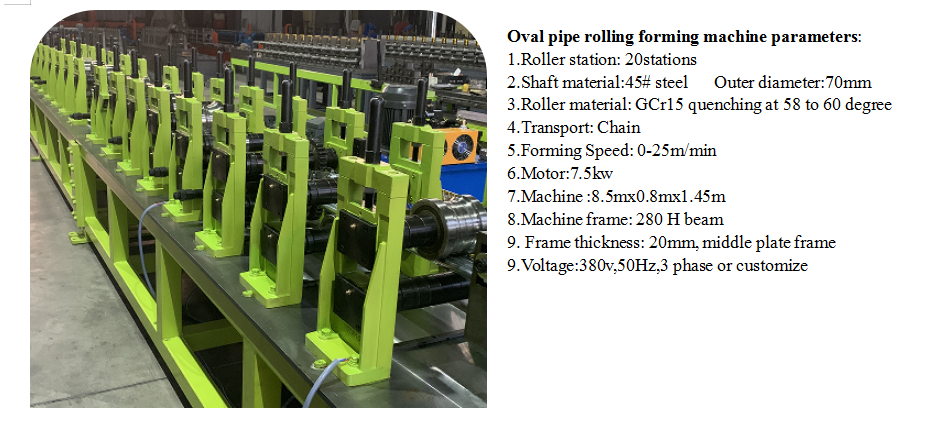

Oval pipe rolling forming machine is designed to make the oval pipe by rolling forming principle. This oval pipe normally are for o electric conduits or electric wiring ducting, And the rolling forming amchine is composed of a 3TON manual decoiler, feeding unit, cooling system, roll forming system, transmission system, cutting system, control system and run-out supporting rack. In the market, normally there are two type design methods: interlock oval tube and welding oval tube. Here we show the small thickness and diameter oval tube by the interlocked method. Drawing profile of the oval tube for your reference:

The raw materials suitable for this oval pipe roll forming machine are galvanized steel or prepainted steel with thickness 0.3-1.2mm thickness, and manual operation is also provided so that customers can easily operate and adjust the machine whenever feeding materials with different thickness. Please note, if the material thickness beyond 1.2mm, then you need to use the welding machine, or second shaping machine to do the shape changing from round tube to oval tube.

Oval Pipe Rolling Forming Machine

How to test the quality of oval tube size?

RFQ About the interlock oval tube rolling forming machine:

Question: For the oval tube, one machine can make many sizes?

Answer: by one set of mold, it is not possible, but we can make the fast change type that means, you can save some cost of common part like decoiler, PLC shearing, motor and others. Fast changing design mean, simple put all rollers and shaft on some base frame. Simple change the base frame and then okay. As to the design difference, fast change also could be economic type or high quality type. We can design machine fully according to customer requirements.

Questions: What is interlock and how is the different with welding?

Answer: Interlock means make the seaming by bending and folding method to make seam closed. It only good for the thin sheet within 1.2mm. When thickness beyond 1.2mm, the only method to close seam then by welding, like TIG welding , laser welding or HF welding.

Questions:How to overlap from one to another?

Answer: For the machine we designed necking machine to make one tube size smaller with ribs and then it can insert to another tube. By this way , one tube can be connected with another tightly. Here are some pictures for your reference:

Oval Pipe Rolling Forming Machine-Interlocked type machine working video with necking, overlapping whole process: