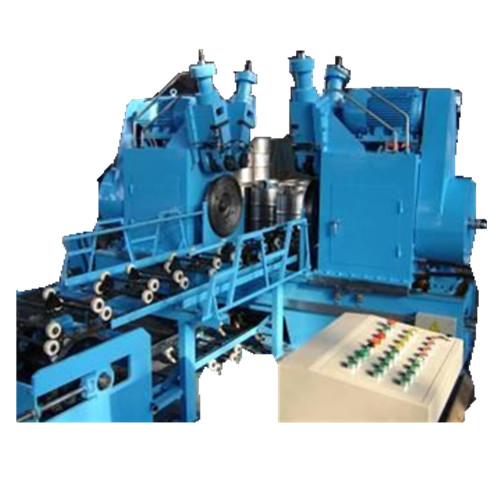

STEEL BARREL PRODUCTION LINE - ZTRFM

Zhongtuo steel barrel production line

According to the barrel sizes difference, we have different mode production lines like 10 PC per minute, 5 PC per minute or 2 to 3 PC per minute.

Meanwhile according to the speed difference, we also have different options for you to choose.

Here we take the following barrels as examples to show you the elements of the production line:

Steel drum production line

Solar barrel productional line

Hydraulic Decoiler of options 5 Ton, 7 Ton, 10Ton or More Bigger.

The loading car, you can choose to add or not.

1.1.1 Up-Coiling Support Platform

1.1.2 Material Feed Trolley and Hydraulic Support Lifting Unit

1.1.3Transmission Device and Hauling Chain

1.1.4 Light Rail

Function

By the loading car, you can put the coil to decoiler shaft, hydraulic expansion for tighten the coil. It is operated with hydraulic system to push cylinder for reciprocating linear movement and gear box to deliver steel coil in parallel to the center of uncoiling unit so as to assure the fixing.

Leveling and cut to length part.

From decoiler to leveling system and then cut to specified length. For example, if the barrel need 5 meter length and then we can cut it to 5 meters length. No matter for which mode barrel, cut to length part, could be used as one common unit.

Roller Trans-Line

Cover Pressing Machine, or we can call it as bottom and top shape forming part:

Qty.:2 units

Function:Pressing bottom covers and up covers

Structure:Mechanical

Main Tech Data:

Main motor power:22kW

Double Locking Pressing Machine

Qty.:1 unit

Function:Lock up the Inlet and air hole.

Structure:Mechanical.

Main Tech Data:

Main motor power:7.5kVA

Molds for Barrel Covers

Middle Section Equipment

1.Circle-Bending Machine

Qty.:1 unit

Function:Roll the ready-cut steel into circular drum body.

Structure:Mechanical transmission,Automatic or Manual, multi machines or

single machine working function.

Ø Main Tech Data:

Ø Main motor power:1.5kw

2.Circle Spot-Welding Machine

Qty:2 Units

Function:Spot Welding on Circle Rolled drum body.To weld the seam and the bottom part welding.

Structure:Operated by Man.

Main Tech. Data:

Type:DN3-75

Main Motor Power:75kVA;

3.Seam Welding Machine

Qty.:2 Units

Function:Seam Welding on Circle Rolled drum body. Ø Structure:Operated by Man.

Main Tech. Data:

Type:FN1-150-5

Main Motor Power:150kVA。

- Edge Rib Reinforcing Machine

Qty.:1 Unit

Function:Edge rib reinforce on drum body.

Structure:Mechanical transmission and hydraulic drive,Automatic or Manual, multi machines or single

machine working function.

Main Tech Data:

Edge Width:16.5~17.5mm;

Reinforced Rib Height:8~14mm,distance between two ribs(center symmetry)280±2mm;

This machine can complete edge rib reinforce at one working time to improve tech sizes and precision.

Main Motor Power:22kw,

- Corrugation (“W” Reinforced Rib) Forming Machine

As to which type, we can customize according to your requirements.

Function:Press W Reinforced Rib after edge-bending and Reinforcing.

Structure:Upper set mechanical transmission and hydraulic drive, Automatic or Manual, multi machines or single machine working function.

Main Tech Data:

Main Motor Power:11kw,Motor Power of Hydraulic Station: 7.5kw.