Profile drawing (Material thickness 0.6 mm)

50*50*50*12mm,Material thickness:to 0.6mm,Hole diameter:60mm

C light keel roll forming machine of Section Description

3 T Manual decoiler

1.This part can manually tighten or shrink the core, so that the loading and unloading of the roll is very convenient.

2.This device can tighten the stainless steel coil. Because the stainless steel coil is very narrow, the coil with a long outer diameter is easy to become loose during use. A longer tightening device can be customized for you to prevent the stainless steel coil from becoming loose , To prevent the interruption of the operation of the door frame equipment, causing danger!

3.The decoiler is equipped with a manual brake. Once a danger occurs during the operation of the equipment into the roll, the operation of the decoiler can be stopped immediately to prevent the occurrence of danger.

Roll forming system of light keel roll forming machine

- The machine is equipped with lifting holes and has been reinforced. The loading and unloading of the machine is very easy, and the machine itself will not be damaged by loading and unloading the machine. As we all know, the machine is prone to loosening a part of the screw or violent packing during the loading and unloading process. The inevitable consequences of machine cracking, painting, bending, etc., will cause serious problems such as deviation and small sides after the machine is running.

- The feed guide roller is made of Cr12 material and is chrome-plated to increase the hardness of the feed guide roller. Some manufacturers use other materials or paint, and there is no difference in appearance, but after a few months of use, the paint will be worn and dropped. , The original material is exposed, and it will rust or be damaged if used for a long time.

- Several rows of such side rollers, also called vertical rollers, are added inside the forming machine. The function of this side roller is to prevent the sheet from deviating, and to make the small side of the sheet perfect, reduce the impact of small side springback, and consolidate Molding effect.

- The machine uses 8.8 grade bolts, which have high tensile strength and yield strength, and have been boiled black, which has strong corrosion resistance. The service life can reach 10 to 15 years. The cost of a bolt is 2 to 3 for ordinary bolts. Double the price. If you use ordinary bolts and use them for a long time, the bolts are prone to loose or rust when the machine is running, which will cause inaccurate forming of the sheet or the machine will not run, damage and stop, which will hinder your business.

5. The nuts for fixing the gantry wall panels are also boiled black and have high corrosion resistance. As we all know, when we adjust the machine or change the mold, we need to remove the nuts frequently. Once they are corroded and rusted, we need to replace the nuts. The cost is also very high, many manufacturers do not carry out this part of the process, our nuts are 2 to 3 times the price of ordinary nuts.

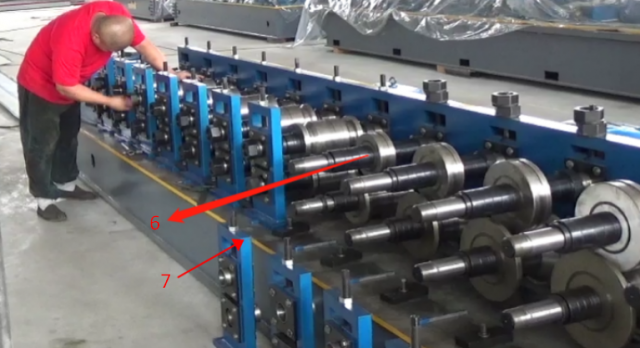

6. The drum is made of Cr12 material, quenched and chrome plated. For galvanized materials, there are very high requirements on the rollers. Some manufacturers did not implement the correct process. In order to save costs, the chrome plating time is short or quenching is not performed, and sometimes only part of the roller is processed. As a result, the roller has a short service life and is easily damaged.

7. The machine wall panel adopts a cast iron arch structure with a thickness of 28mm. This structure makes the machine run more stable.

8.Adopt Omron counter, this kind of counter has long service life and accurate automatic counting.

PLC control system

9.Manual touch screen, and all large screens are used. We use the Delta brand, which is easy to operate, fast and accurate, and can design a variety of parameters and functions.

10.For buttons, we usually use Schneider brand. Common electrical components have a short service life. Once broken, it is difficult to find matching repairs. However, Schneider is a global warranty and the after-sales service is very convenient.

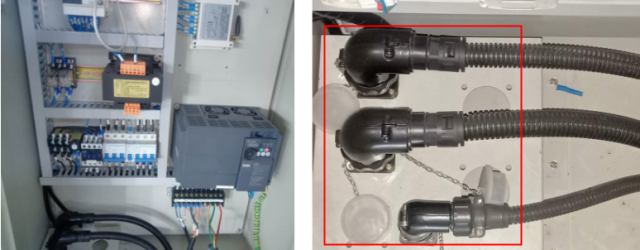

11.Generally, the electric cabinet box in the factory is painted. After a long time, the paint is easy to fall off. The electric cabinet box we use is painted. For a humid environment, it has a long service life and will not lose the paint. Our electric cabinet box shell is more Thicker, reflected in the weight, and stronger.

- The electric cabinet is equipped with an intelligent heat dissipation system, which can run for a long time and has a long service life. The electrical materials are also internationally renowned brands. The original electrical appliances can be purchased as accessories abroad, which are very durable and convenient.

- Using this kind of aviation plug for wiring makes it easy to connect the electricity to the main engine, petrol station, and motor, so we won’t have installation and after-sales problems, and this wiring method is very safe.

Hydraulic oil pump station

14. The hydraulic oil station is equipped with an air-cooled device, and the machine can run for multiple hours without stopping, which will continue to last for your business and have a long service life.

15. The solenoid valve adopts the Japanese Yuken brand, which is durable and not easy to damage.

16. The oil pump adopts new technology and produces very little noise.

17. The tank is thickened and uses a large fuel tank to provide strong power for the operation of the machine, which is 2 to 3 times the price of an ordinary fuel tank. The ordinary fuel tank is prone to oil leakage and cannot be started. This is very durable.

cutting system

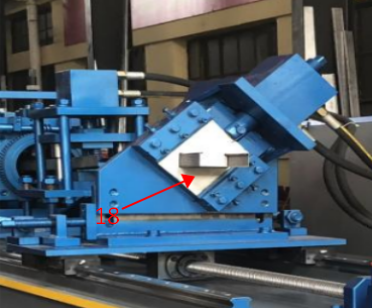

18.The cutting blade is made of Cr12 material and quenched. It has strong wear resistance, stability, compressive strength and other characteristics. Will not bend or crack after long time use. Galvanized material has better cutting effect and is very durable.

product collect table

19.This kind of material receiving rack can be manually packaged while receiving materials, which is convenient to operate and practical and stable.