GUARDRAIL ROLL FORMING MACHINE - ZTRFM

Zhongtuo highway guardrail roll forming machine

Steel guardrail making machine

Highway Guardrail Roll Forming Machine

What’s guardrail?

Guardrail or Guard rail, is a system to keep errant vehicles from straying into dangerous areas of highway. The thickness of the guardrail can be up to 4.5mm.

The Types of Guardrail

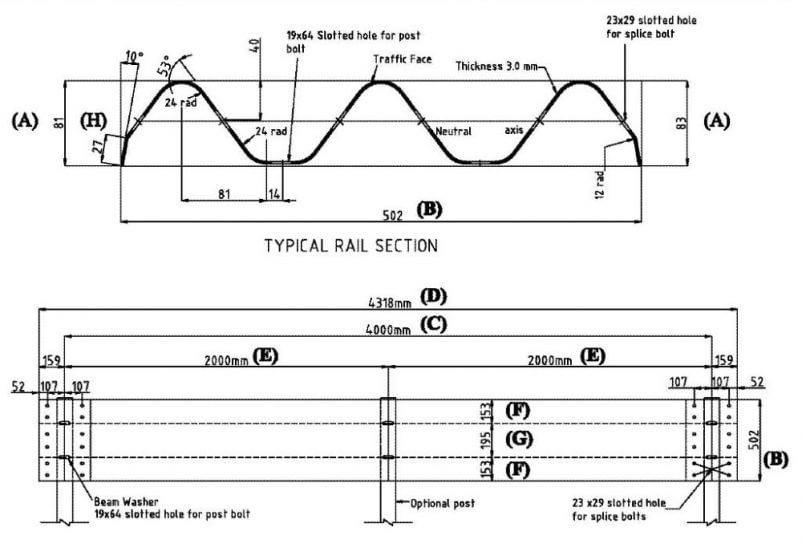

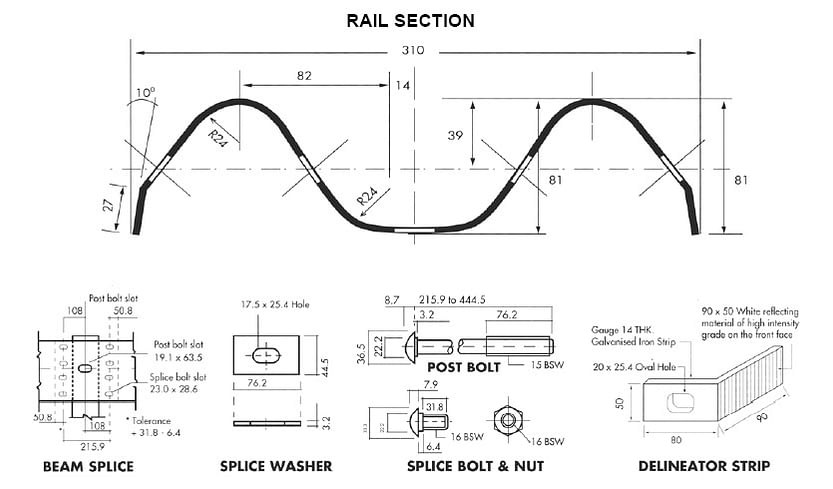

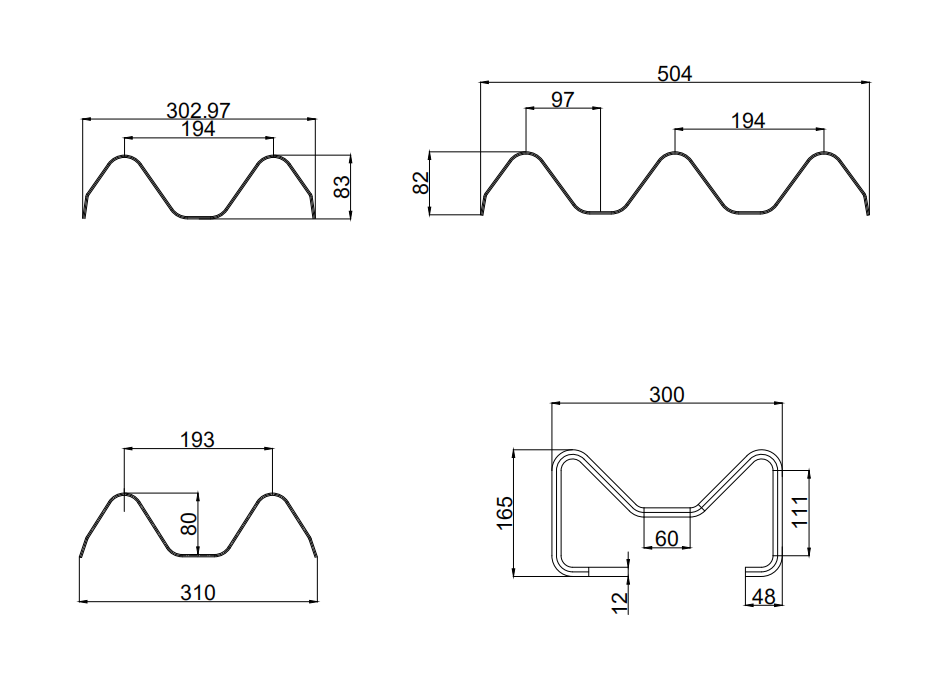

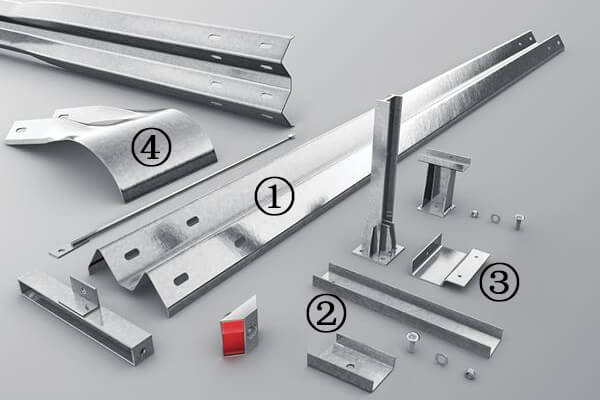

The most common type of Guardrail used now is W-Beam. also called two waves guardrail. And now Thrie-Beam guardrail is new one and which is a type of guardrail that is similar to two pieces of W-Beam Guardrail formed into one single section.

Two waves guardrail, W-beam guardrail is widely common used in the whole world.

Thrie-beam, also named three waves guardrail, which is for heavy requirement

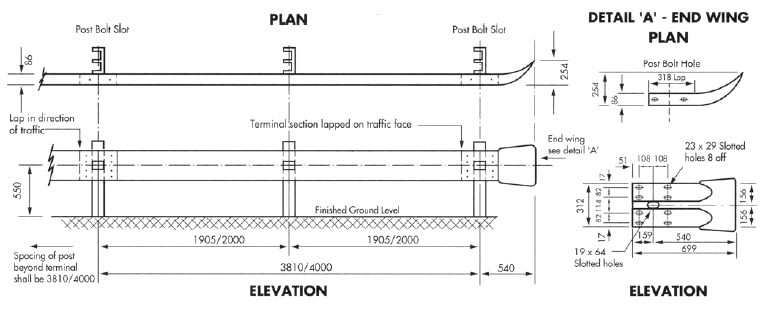

The end of the guardrail usually formed as a wing type

Guardrail wing end is the ends of every group of guardrail system

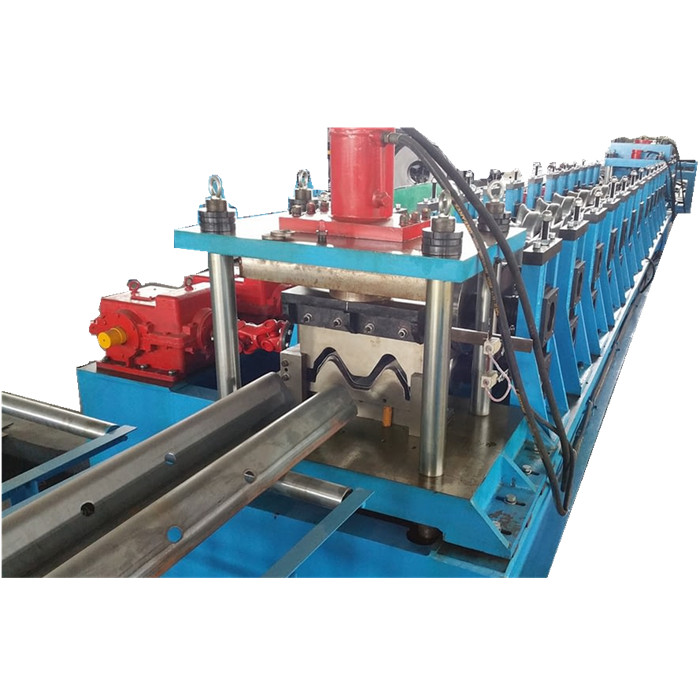

The Layout of Highway Guardrail Roll Forming Machine is Uncoiling– Leveling– Punching– Cutting–Roll Forming– Auto Stacking

M/C of Highway Guardrail Roll Forming Machine

5 Ton Hydraulic Uncoiler

- Electric uncoiling, hydraulic loosen and tension

- Maximum capacity 6 Ton

- D:D:1350mm

- Maximum width350mm,

- Structure:Steel plate and Beam Welded

- supporting and uncoiling the steel strips.

Feeding and Leveling Device

The feeding, leveling device is for feeding and leveling the coil strips before punching and roll forming

- Feeding Type: Adjustable

- Feeding Width Range:660-800mm

- Entrance And Guide Roller: 45# steel, ¢65mm, HRC48-52° surfacechromed

- Leveling Roller: Upper layer 4 rollers, down layer 5 rollers, totally 9 rollers

- Leveling Roller Material: 45# steel, thermal treatment hardness 48-52 HRC.

- Leveling Shaft Material: 45# steel, ¢76mm, hardening and tempering

Punch Hole device

- The punches will be connected to a single hydraulic unit with tank, motor, pump, pressure control valves, pressure gauges, solenoid valves, hydraulic hoses, all designed to operate safely at the required operating pressure.

- The punches and doilies will be CR-12, HRC 58-62 and chrome coating. Both punches and doilies should be easily replaceable without disassembling of the whole units.

- The whole punching operation will be automated and controlled by a program installed in the PC which is located in the operator’s console.

- Hydraulic Power: 15kw

Roll Forming Machine

- .Thickness Range: 0-3.2mm

- Forming Speed: Not less than 10m/min (Not including punching and cutting)

- Main Motor Power:22kw, ABB Brand AC Motor

- Machine Voltage, Frequency, Phase:415V, 50Hz, 3Phase

- Roll Station:16 stations

- Roller Material:GCR15, HRC58-62, with surface chromed,CNC

- Shaft Diameter: ¢76mm, Material: 45# steel with quenching and tempering

- Transmission:By gear box, totally 16 groups

- Machine base frame adopt H Beam steel welding

- Buttons in the main roll forming machine for urgency stop if any malfunction.

- Machine station adopt cast iron type to make it strong and stable.

- All of driving part cover with protection mesh to avoid accidents.

Cutting Off Device

- Cutting Type: Hydraulic cutting, connect with the punching hydraulic unit

- Motor Power:15KW

- Hydraulic Cutting After Forming: Cut guardrail panels after roll forming to required length

- Cutting Motion: The roll forming part stops when cutting

- Material Of Cutting Blade:Cr12 with heat treatment

- Length Measuring: Automatic encoder length measuring;Brand: Omron

Tolerance Of Length: +/- 1.5mm Each piece end product

Brief specifications

- 5 Ton decoiler

- Forming Steps: 18

- Roller Material: GCR 15, quenched and tempered. Hardness treatment 58-62°

- Shaft Material: ASTM 1045, 90mm O.D, heat treatment ment 58-62°

- Main Motor Power: 22KW

- Hydraulic Power: 22KW

- Line Speed: 15m/min, exclude punch and cutting

- Cutoff Blade Material: CR12 MOV

- Siemens PLC

- Yaskawa frequency converter

- Omron encoder and limit switch