PU DOOR SHUTTER ROLL FORMING MACHINE - ZTRFM

Zhongtuo PU roller shutter door machine

PU roller shutter door roll forming machine

Zhongtuo PU roller shutter door roll forming machine

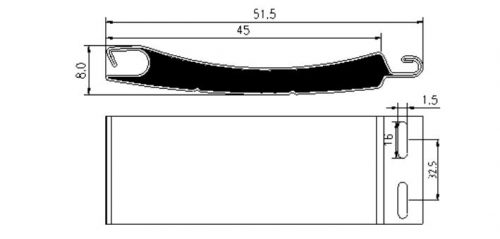

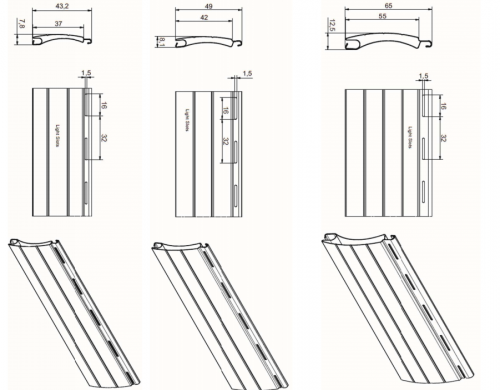

Zhongtuo cold rolling forming machinery Supply, Install, Maintain, Service And Repair A Wide Range Of Roller Shutters Roll Forming Machine and within a short period of time it turned out to be one of the most distinguished companies in Security rolling shutters roll forming machine and outer PU Foam Roller Shutter Door Roll Forming Machine industrial branch. we can produce a wide range of industrial doors includes sectional overhead doors and roller shutters and fire roller shutters and security doors also PU Foam Injection Shutter and etc.Steel roller shutters are very versatile and come with various options.PU foam shutter door section which is ideal for showrooms. So we take the following drawing profile for example to show you the PU roller shutter door roll forming machine designed.

The machine is composed by the following elements

| 1 | Decoiler | 1 set |

| 2 | Guide Feeding device | 1 set |

| 3 | main forming machine | 1 set |

| 4 | PU Foaming machine | 1 set |

| 5 | Straighten device | 1 set |

| 6 | flying saw cutting machine | 1 set |

| 7 | finished products table | 1 set |

| 8 | PLC control system | 1 set |

| 9 | Spare Parts And Tools | 1 set |

Supported material

Material: Galvanized Coil,Aluminum Thickness: 0.3-0.5mm

Main roll forming machine Power: 7.5 Kw

Forming Speed: 10-12m/min

Feeding width: 229mm

Production line N/W: about 8TProduction line length: about 38m

Impassive to expanding

Roll Forming system with feed panel unit

Axis Diameter:50 mm

Forming Roller station:36+1 groups

First grade 45# steel:Main Axis material heated and quenched First grade 45# steel,

Roller material:Hard Chrome Coated,heated and quenched

Pillar size:42*45mm

Forming Speed:10-12 m/min

Drive Type:Model 110 Gear boxWelded structural steel,

Machine Frame stand: thickness 10mm

Cutting Device: Servo tracking cutting

Cutting system power:2.2KW

length tolerance:士0.5mm

PU Foaming Untit: Mixer type

PU Raw material tanks

2nd generation

No-block nozzle