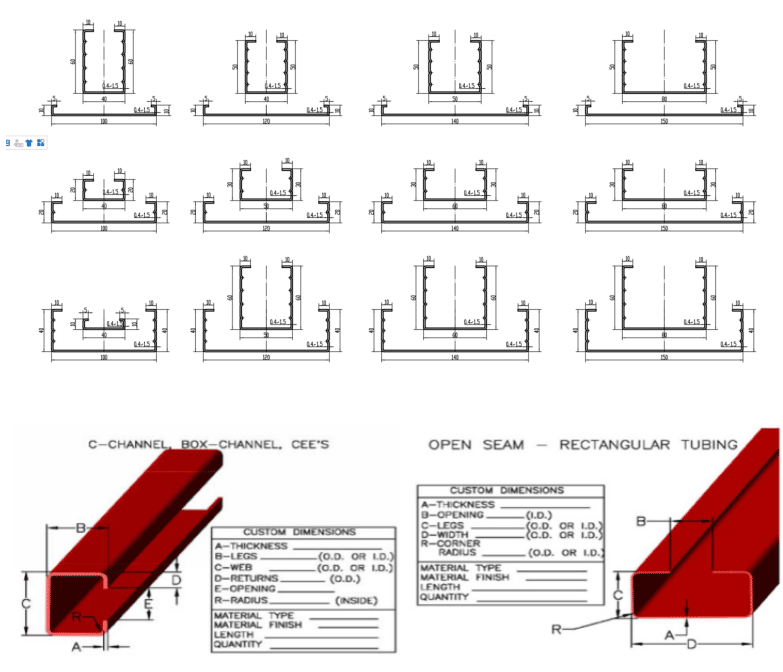

Automatic C-Channels rolling making machine is designed to make the many sizes C profiles by one machine. C Channel & Box Channel thicknesses vary from .003″ thick up to .150″ thick. On 1/4 & 1/2 hard aluminum, Aluminum C Channel & Aluminum Box Channel thicknesses can reach up to .250″ thick. Many different decorative pre-coated metals are generally not recommended when more than .030″ thickness is required unless larger than normal corner radii can be used. Some coatings can be used, however, up to .125″ thick such as a pre-finished Hot Dip Galvanized coating. Box Channel & C-Channel Lengths may be from 3″ thru 40 feet long with close tolerances. Many different lengths can be put on one purchase order. Here are some sizes for your reference:

Specification of automatic c channel rolling making machine

|

Main roll forming machine |

|

| Note: We use split rollers to realize one machine to produce C profile products with different bottom widths. | |

| Voltage | 380V ,50Hz, 3Phase (as customer request) |

| Frame type | Memorial arch frame of thickness 30mm |

| Drive mode | Heavy duty gearbox as transmission |

| Material of rollers | GCr12mov |

| Material of shafts | 45# steel with tempering |

| Diameter of shafts | Φ70mm |

| Number of rollers | 15 rollers With more rib roller one more station and 4 sets rib adjustable rollers |

| Main power | 7.5 kw and with one more motors 11kw |

| Raw Materials | Galvanized steel plate |

| Material thickness | 0.5-1.5 mm |

| Forming speed | 50 m per minute without punching hole |

automatic c channel rolling making machine features:

- Sizes are adjusted by PLC fully automatically. The shaft with rollers are movable.

- Handrail at the leveling part with guiding system, for feeding coil easily.

- With oil drops to cool the roller and make it durable and use for a long time.

- Gearbox transmission to make sure fast speed. For our machine the speed could be adjusted from 25 to 120 meter per minute.

- Separated rollers for sizes adjustments.

- Use two motors for main transmission system to give the power evenly.

- Use servo motor for tracking shearing.

- Use energy tank for non-stop punching and shearing. By this way, the shearing is more beautiful no bur.

- With the adjustable embossing rollers and ribs, you can make them according to your own design.

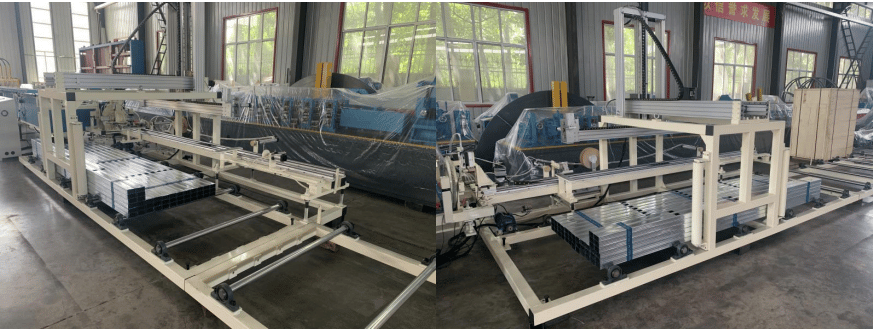

About the package system:

When the machine working in high speed, the workers are hard to do the collection of the stud and track. Then you can choose the automatic package system, it can help you package the profiles orderly and then package them well for loading.