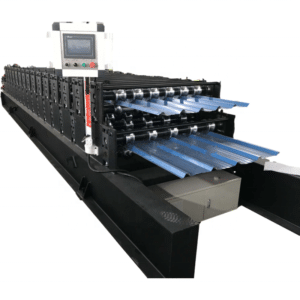

High quality metal roofing sheet machines to Bahrain

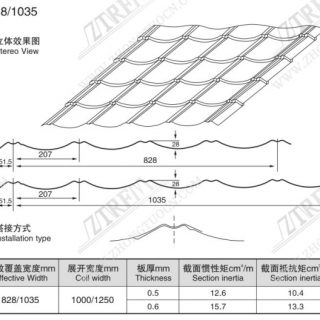

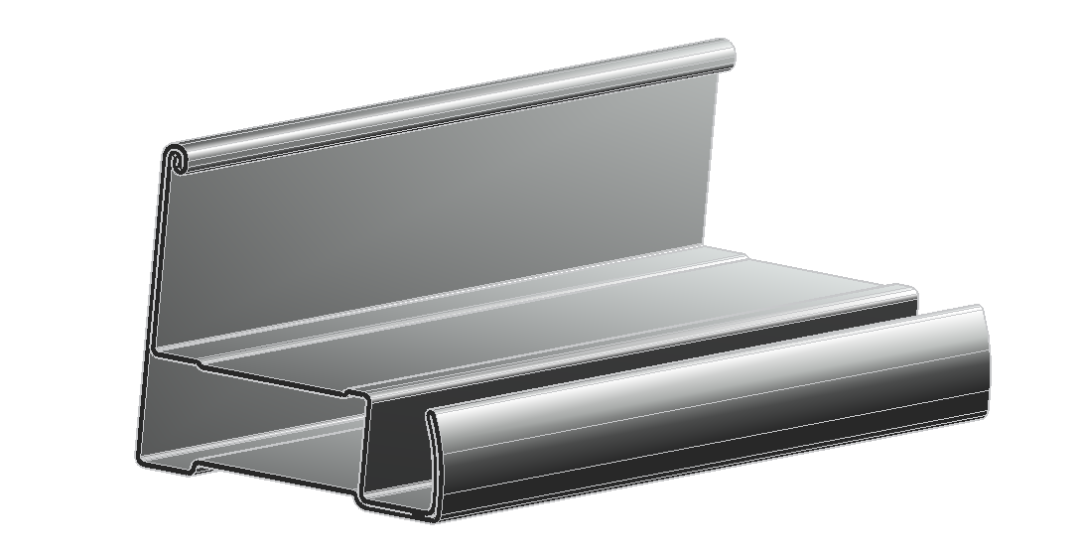

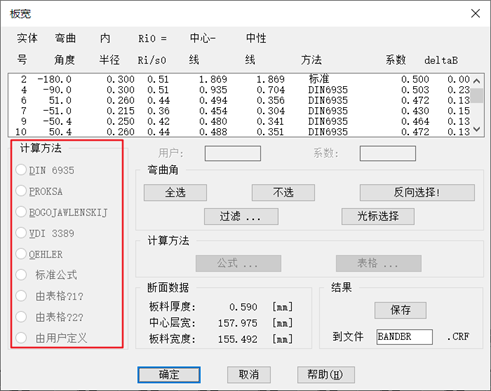

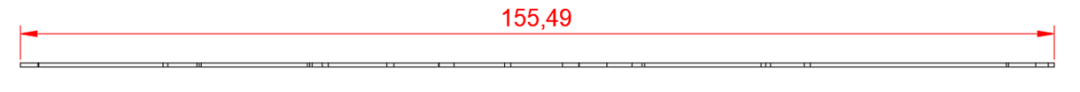

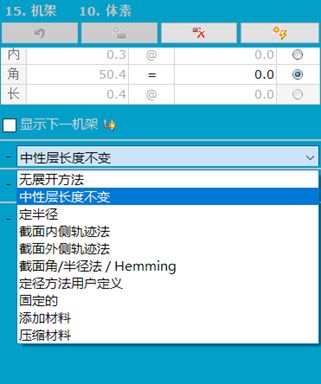

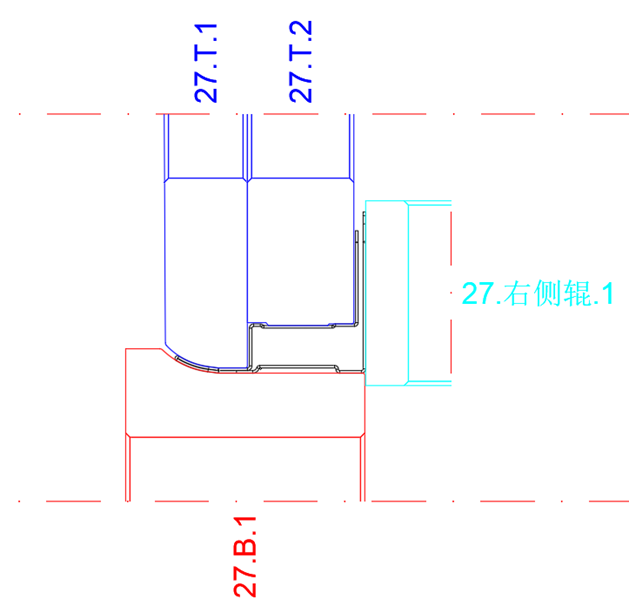

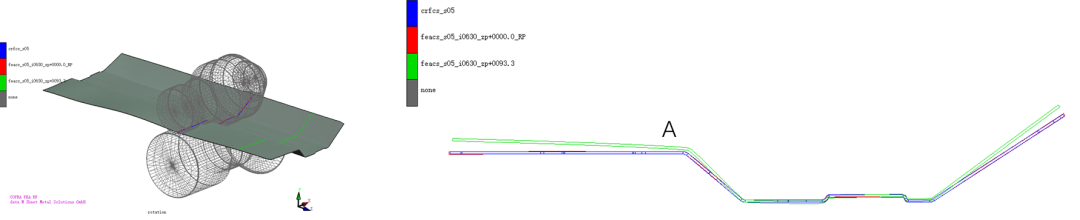

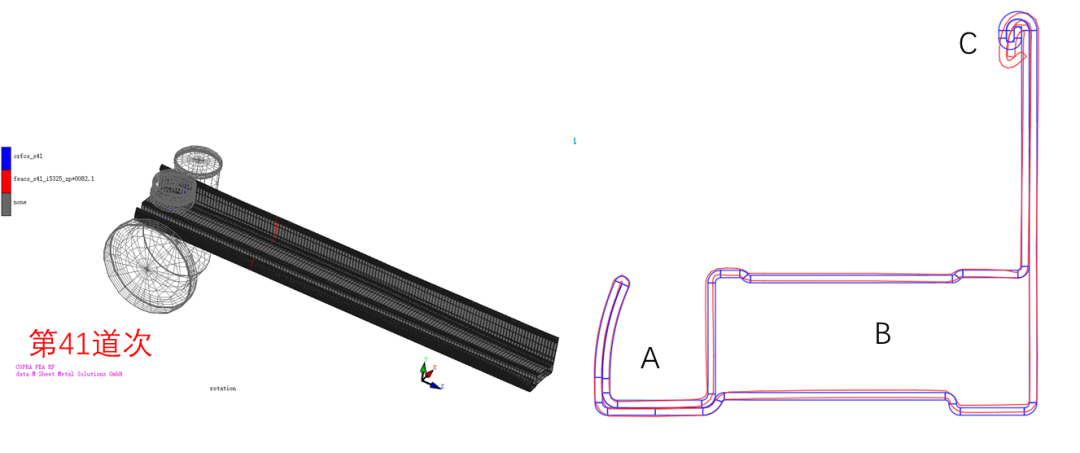

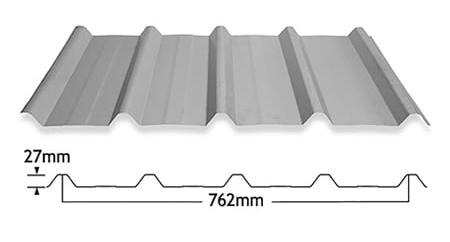

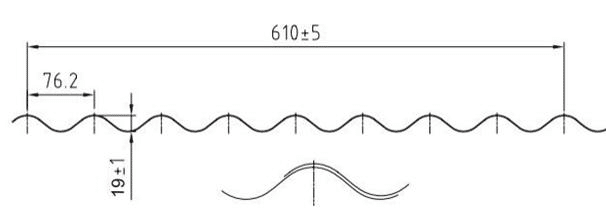

High quality metal roofing sheet machines to Bahrain is designed fully automatic type with hydraulic decoiler, gearbox rolling forming machine and automatic stacker. Here I will take the drawing profile we made for your reference to show you how the machine is designed:

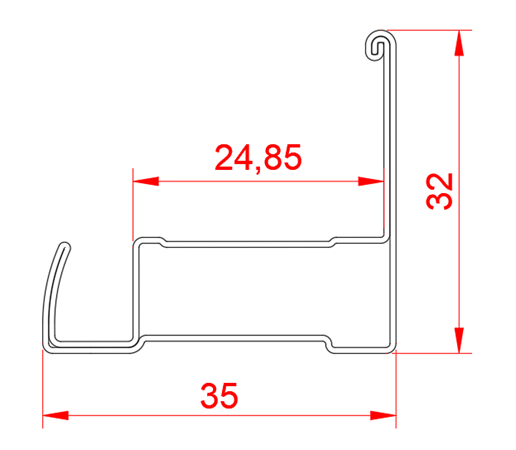

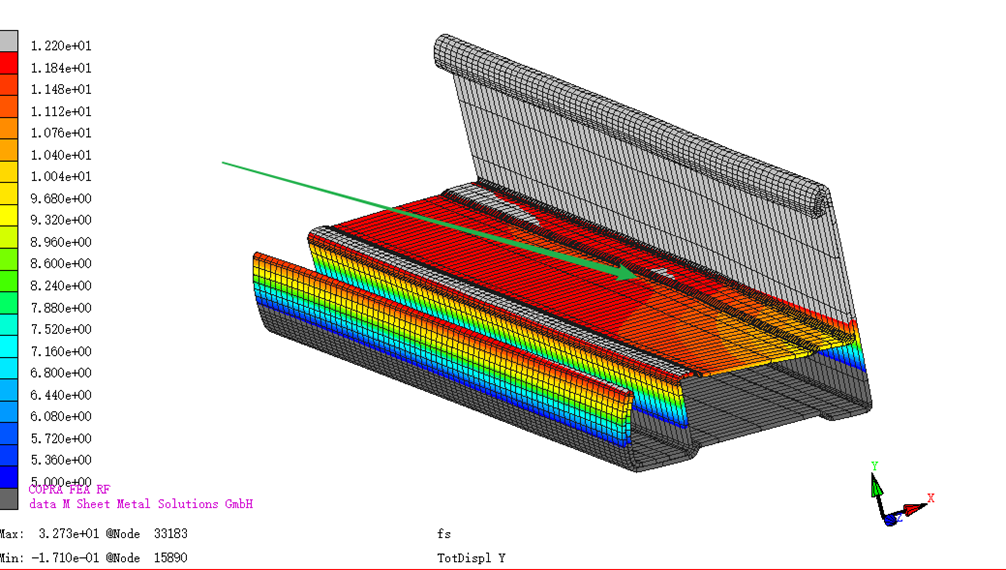

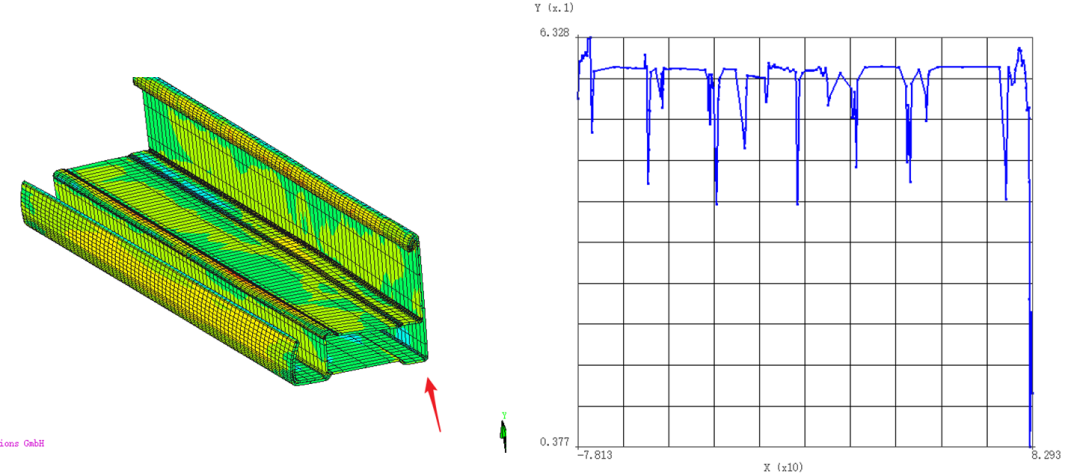

For this drawing profile is quite popular in Bahrain, it uses the 122mm input coil width and then make the valid width 1000mm sheets. The wave height is 31.5mm.

Wave distance is 200mm with two ribs.

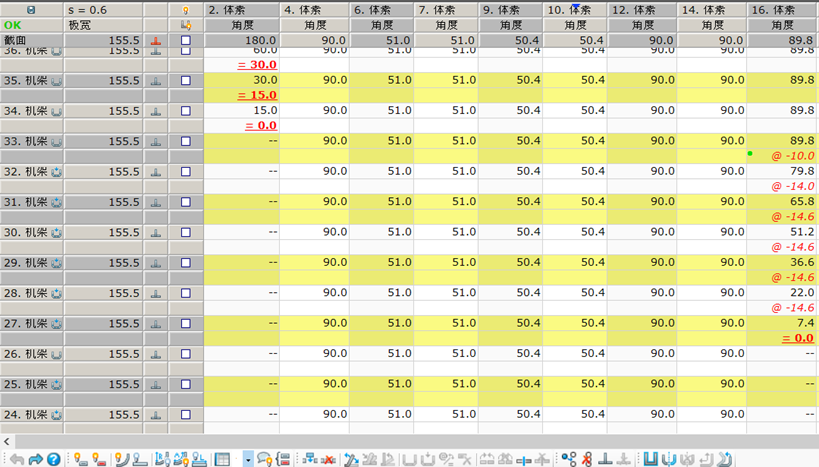

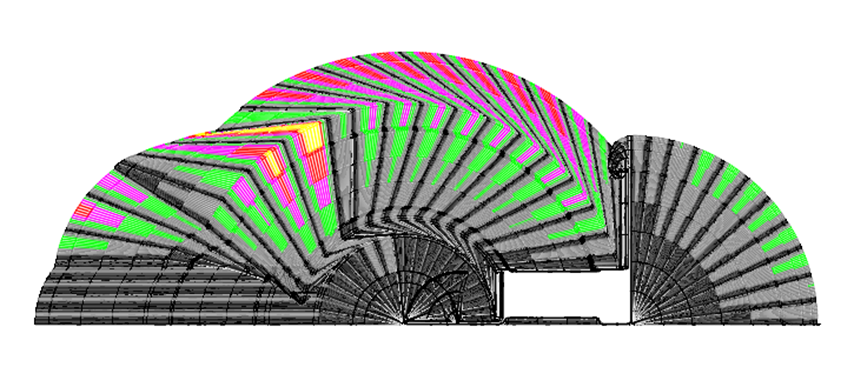

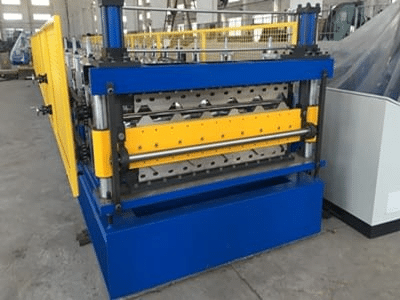

High quality metal roofing sheet machines design for your reference:

First Part: Hydraulic decoiler design:

- Equipped with world famous brand “Schneider” electrical parts safety and reliable.

- Easy to change.

3.The operation of the equipment is more safe, reliable and stable.

Pneumatic braking system

1. Can stop the rotate of coil immediately when required, avoid unnecessary coil output.

2. Fast braking, more safer.

3. The matching high-speed forming machine needs faster uncoiling speed, and the pneumatic brake can provide greater braking force. Customers need to be equipped with their own compressed air source.

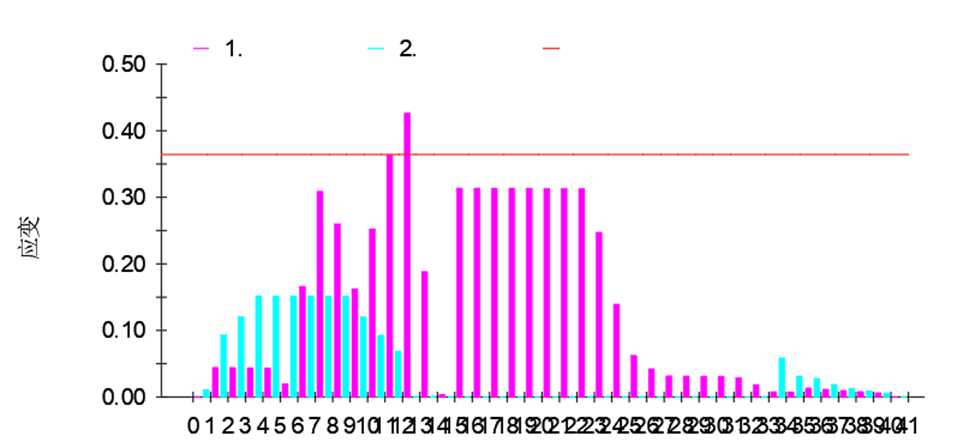

| Series | Details | Parameter | |||

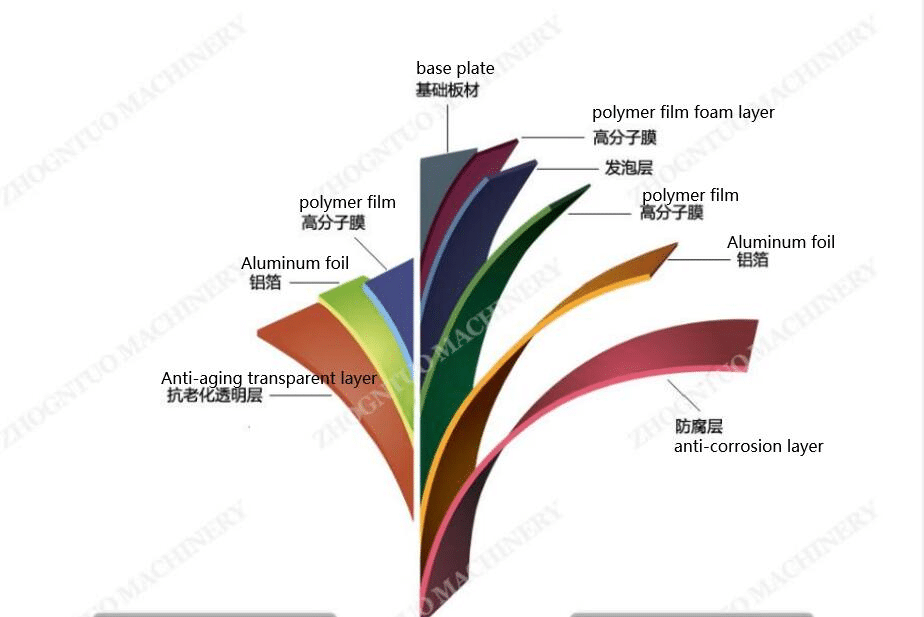

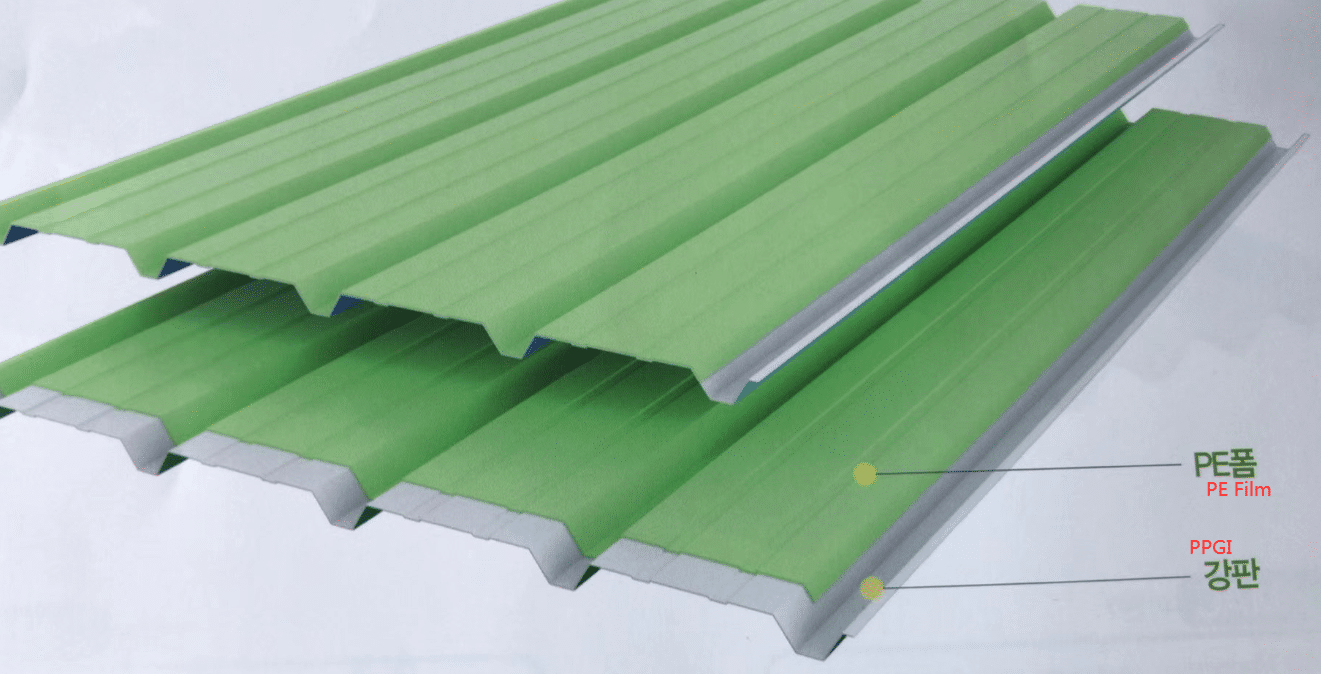

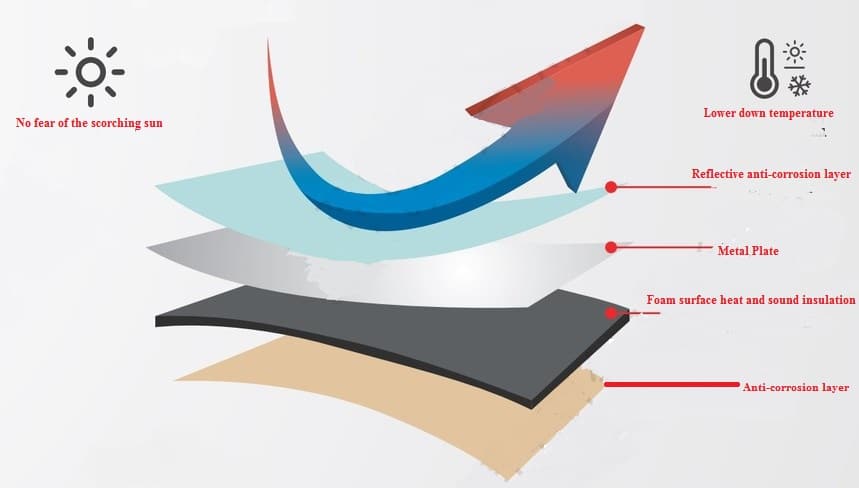

| Product sheet | Raw material | PPGI/GI | |||

| Material thickness | 0.2-0.8 mm | ||||

| Material feeding width | 1100 mm | ||||

| Product effective width | 914.4 mm | ||||

| Product cutting length | Adjustable | ||||

| Packing list-sliding profile roll forming machine | |||||

| No. | Name | Unit | Quantity | Remark | |

| Part 1 | 7 T decoiler with loading car | set | 1 | Automatic | |

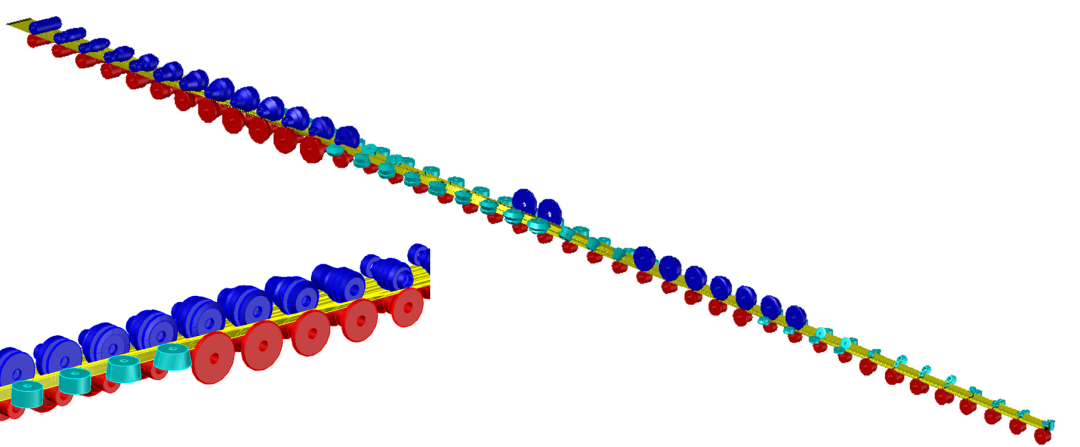

| Part 2 | Main roll forming machine | set | 1 | Gear box drive | |

| Part 3 | PLC control station | set | 1 | Delta brand | |

| Part 4 | hydraulic system | set | 1 | For cutting | |

| Part 5 | Product automatic stacker | set | 1 | 6m length | |

Metal roofing sheet machines

- The plastic rubber roller at the feeding port can protect the paint surface from scratches and is convenient for feeding.

2. External gears increase the transmission speed to ensure the stability of the equipment.

3. Gear box transmission, speed up fast, ensure that the molding is completed with the minimum force, and increase the service life of the equipment.

Automatic stacker 6 meters or 12 meters optional:

1.Auto stakcer for reception of the cut profiles: allows free unloading of each cut profile and automatic placement on the stack of previously made products,

2.Stacking principle: the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet;

3.Unloading of the finished products (moving of the stack of finished products from the production line): mechanic, it will be possible to pick the stack using a fork-lift or in a similar manner (fork-lift will be provided by customer).

4.Max. Length of the sheet: 6000 mm

5.Max. Width of the sheet: 1250 mm

6.The thickness of stack: 300 mm

7.Unloading Power: pneumatic (the air pump is provided by the user)

8.Stack table is moveable (left-right)

9.Transmission power:3 kw

10.Drive of transmission by 1.0 inch double line chains

11.Color: blue or base on customer request

12.Stacker dimension:6500 mm×2100 mm×1600 mm

High quality metal roofing sheet machines to Bahrain working videos for your reference: