Arch metal curve roofing forming machine is designed to do the crimping or curving on the metal roofing sheets. It can be used to make the curve roofing itself; it can be used to make the curveing by bending degree. Normally speaking, each punching it can change 10 degree and the punching degree is adjustable.

Not all the shape could be made by the Arch metal curve roofing forming machine, her I take some sample to show the machine design and how it works.

For the arch metal curve roofing forming machine, it handles the metal roofing sheets like this. When do the curve roofing sheets, it handles like this:

Arch metal curve roofing forming machine design like this:

Main parameters of arch metal curve roofing forming machine

| 2 | Dimension of line | Main machine:2300*1650*1600mm |

| 3 | Weight | About 1.5T |

| 4 | Feeding roller material | 45# high steel,machine by CNC, chormed 0.05mm |

| 5 | Shafts | 70mm |

| 6 | Feeding steps | 2 pass |

| 7 | Main motor power | 3Kw Stepper motor(run accurately) |

| 8 | Hydraulic motor power | 4Kw |

| 9 | Voltage | 380V/3phase/50HZ(or as your requirement) |

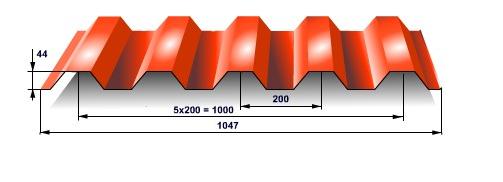

| 10 | Material | Color steel plate |

| 11 | Drive type | Wheel gear driving,running by stepper motor |

| 12 | Thickness | 0.3-0.8mm |

| 13 | Crimping mould | Cr12 high steel,quenched |

| 14 | Productivity | 5-10m/min (not including the cutting time) |

| 15 | Control system | Delta PLC box with inverter, ouch screen |

Here are some parameters of the Arch metal curve roofing forming machine for your reference:

Arch metal curve roofing forming machine finished products for your refernece:

For this machine, if you want to know more information, please contact us at any time.