Sandwich Panels half automatic rolling machine Down layer or for wall panel rolling machine - ZTRFM

Sandwich Panels half automatic rolling machine down layer or for wall panel rolling machine is designed to make the sandwich panel sheets in a separated methods. Different with the fully automatic sandwich panel machine, by this type machine, you need, to make the down panel first and then upper layer machine. Meranwhile it needs another machine to press them together.

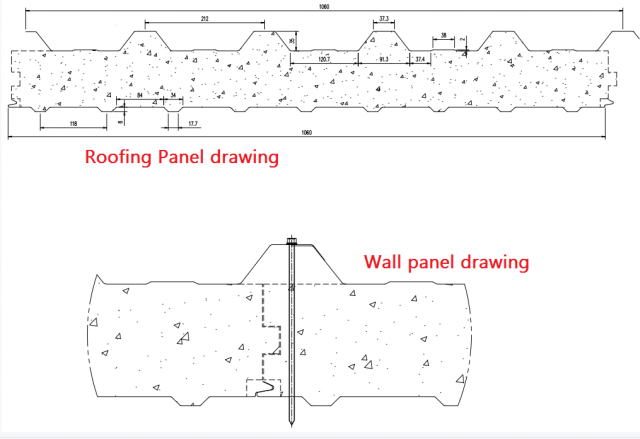

Advantage of this half automatic sandwich panel machines: it can either be used to make the EPS sandwich panels, PU sandwich panel and others: EPS Sandwich Roof Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core high density EPS foam. Thanks to their properties the panels may be applied in object that require very high fire resistance, EPS sandwich panel is the most effective acoustic materials used on construction. Here I take a random drawing profile for your reference:

EPS Sandwich Panel-roofing panel:

Sandwich Panels half automatic rolling machine down layer or for wall panel rolling machine:

Half automatic rolling machine wall panel rolling machine for making down layer of the sandwich panel:

This machine is not easy to make as the special edge shape. When rolling, we need to conside the edge shape should be nice and easy to installation. When do the installation, the down and upper layer could be connected tightly.

When come to shearing, we need to make sure the shape not change. So we design the machine using 3 pieces cutting blade to cut. Even if there is some wasted coils, but we feel it is more important to keep the shape.