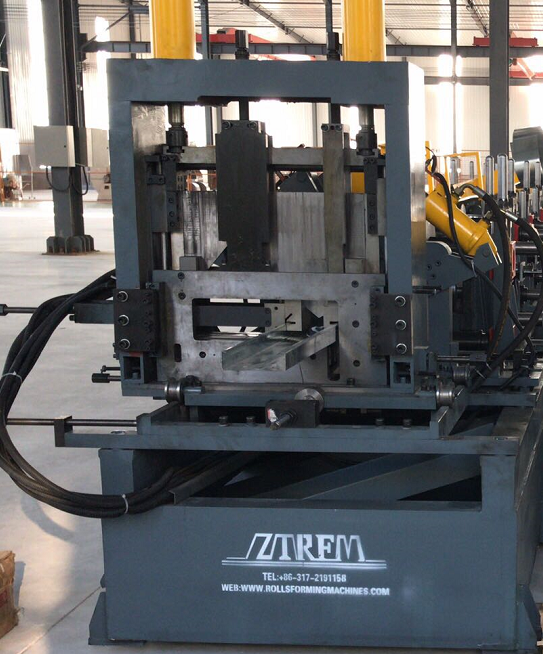

Purlin Roll Forming Machine C Z W Steel Building Materials Machinery Engineers Available to Service Machinery Overseas Automatic - ZTRFM

C shape purlins are made from cold rolled steel strips, through straightened, hole punched, cut to lenght and roll formed by steel purlin roll forming machine. By changing the spacer bush, the machine can make many purlin with different sizes.

Steel purlin roll forming machine consist of uncoiling system, straightening system, hole punching system, cutting system, roll forming system, product receiving table, hydraulic system, automatic controllinig system and so on. Our company has dozens of profiles for this serious roll forming machine. We can design different kinds of profiles and configurations for purlin machine as per customers’ requirements.

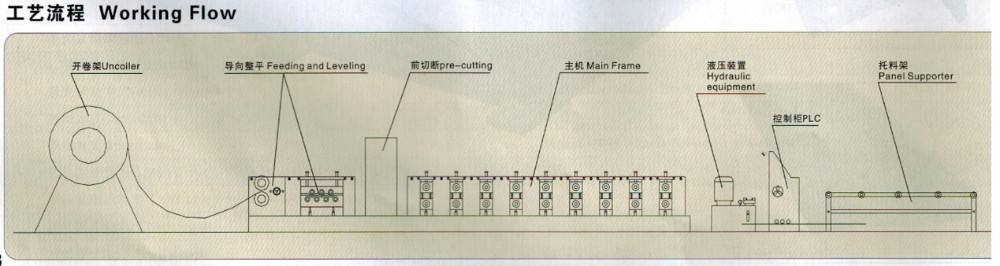

Working flow:

Uncoiling—-> Sheet Guiding—>Straightening & Levelling—> (Hole Punching)—->Measuring Length & Cutting—->Roll Forming——> Sheet to Support Table

Main technical parameters of steel purlin roll forming machine:

| Model | ZT series | ||

| Profile | C Zpurlin | ||

| Unit(mm) | 100-250 | ||

| Material | Type | steel strips | |

| Thickness(mm) | 1.5-3.0 | ||

| Yield stress(Mpa) | 230-300 | ||

| Max. Forming speed(m/min) | 0-20m/min | ||

| Material of roller | Bearing steel | ||

| Driven mode of roller | chain transmission | ||

| Controller | PLC | ||

| Operation | Touch screen and button | ||

| Pressure of hydraulic station(Mpa) | 20 | ||

| Motor power for hydraulic station(KW) | 5.5 | ||

| Motor power for roll forming part(KW) | 18.5~22 | ||

| Total power(KW) | 24~27.5 | ||

| Total weight(Kg) | About 10 tons | ||

its own factory and also cooperate with several production factories and associated nterprises, concerning with

the design, development and production of cold roll forming machines,material of building. It is located in

northwest of CangZhou, as a long history of cold roll formingmachine production base. All products comply

with international quality standards and are greatlyappreciated in variety of different markets throughout the

world, such as Asia, Africa, Europe,South America, and Australia and so on.