Technical sheet

- C purlin drawing profile:

Material thickness:1.0-3.0mm

Material:Q195,Q235 hot rolled steel or hot rolled galvanized steel coil

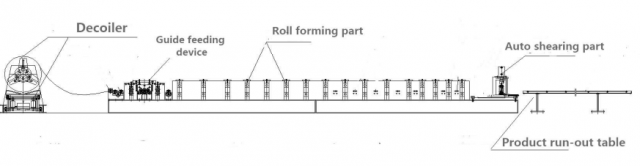

- . Processing flow diagram of machine

- Production process

Uncoiling→ Feeding material into machine →Roll forming → Auto shearing→Products receiving table

- Technical parameters:

Manual decoiler

1.Capacity: 5 ton

2.Coil inner diameter:450-550mm

3.Structure: welded by the steel plates and profiled bar.

4.The shrink and expand of core is manually, with manual brake

5.The coil moving forward or reverse is pulled by purlin roll forming machine

Guide feeding device

1.7 rollers leveling:top three,down four +two lead. Roller material:45# steel,chromed

2.The material of rollers could stop scratching the zinc of the steel.

Main roll forming part

- Machine frame:350mm H beam structure , 300H supporter

- Roller quantity:18 sets,one roller forms the height of waist between 87-95 degree. size adjustment is controlled by electric

- Roller Material:Main rollers:GCr15 Supporting side rollers:Cr12

Roller Processing technology: rough moulding

+ high frequency heat treatment HRC50-55 ℃

+ accurate grinding + surface polished + hard chrome

4.Shafts Material:Motor drive shaft: 40Cr steel Other roll shaft: 45# steel

Processing technology: quenching and tempering treatment HB210-230+ rough car + cylindrical grinding + polishing surface hard chrome plating

5.Motor power: 18.5 KW

6.Forming speed: 0-30 m/min

7.Transmission way: By chain

Auto shearing part

- Unbridled shearing system, you can cut all size products by adjusting the blade,it is much easier than traditional shearing system.

- PLC automatic size adjustment,you can adjust the rollers by using buttons on the PLC cabinet screen,it can save a lot labor and

3 . Blade material: Cr12.the blade is very hard and durable.

PLC control station

1.Main accessories origin: PLC (Panasonic), touch screen (Delta), electrical components (Schneider), length encoder (Japan Omron)

2.All of these parts are world famous brands, accurate and durable,and if it doesn’t work,you can buy parts very easy.

3.Language:Chinese and Spanish(as required)

Hydraulic oil pump station

1.Power:5.5KW

2.Fuel tank volume:500 liters

3.Solenoid valve: Beijing Huade

4.Cooling type:fan cooling

Product run-out table

1.Length:3m

2.Quantity: 2 sets

3.Structure :the frame body is welded with angle steel and angle steel, and the surface is loaded with rollers.

It is very simple and welcomed by many customers,low-cost and portable.