High speed step tile roofing sheet rolling forming machine - ZTRFM

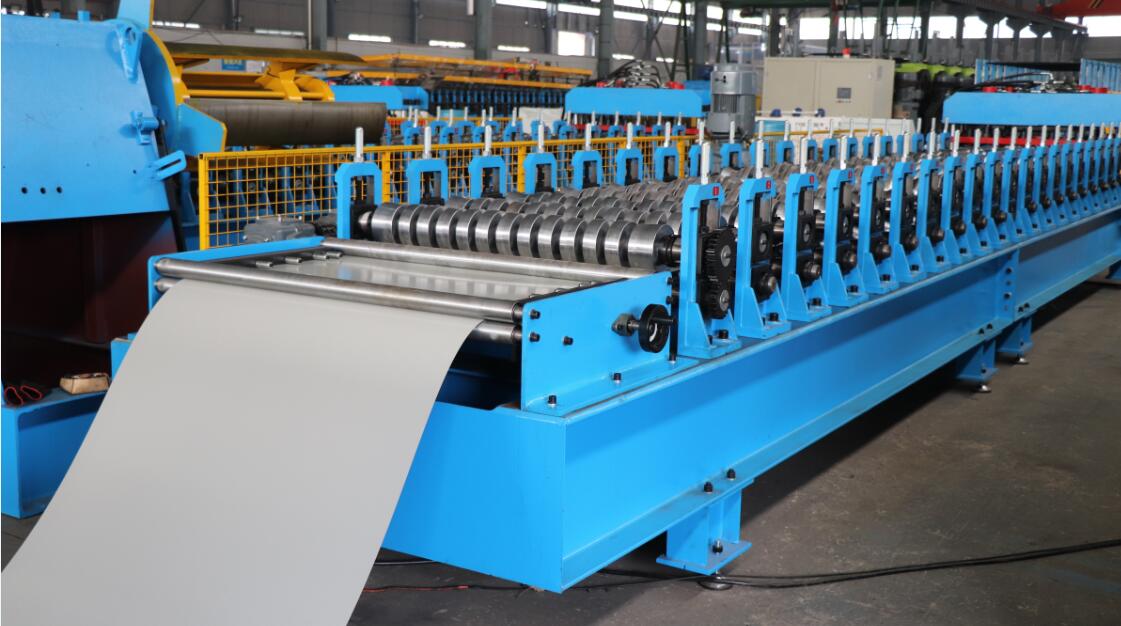

This high speed step tile roofing sheet machine can reach the working speed is around 8 to 12 meter per minutes. It uses the servo technology to increase the roll-forming speeds up , enhance the precision stamping step, and allows for smooth operation while saving on electricity usage. Meanwhile at the shearing and stamping part, we use the whole mold framing design.

It is easy operation through a friendly “human-machine” interface with multiple language settings, optimizing setting-feature on the multi-color touch screen. Its modern design is structurally strong and stable.The rollers and molding system are of a high quality, standardized designed, machined on modern CNC machines and undergo rigorous testing. As a result, the waveform is very sharp and synchronized.

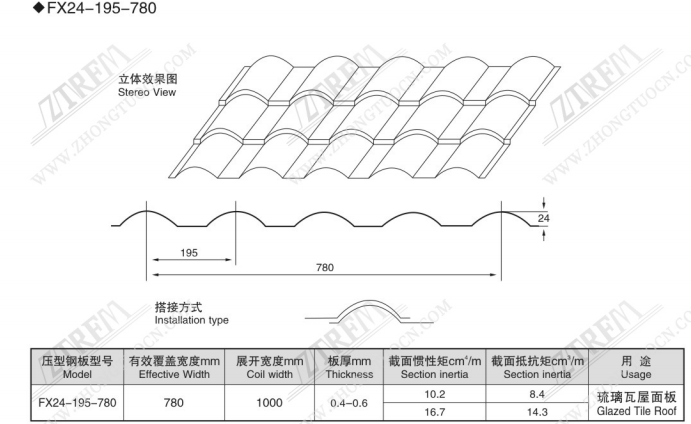

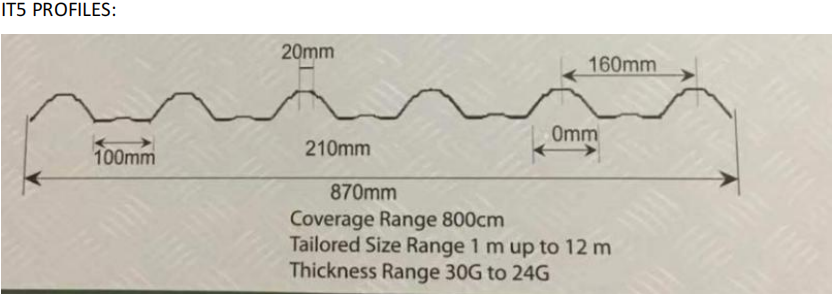

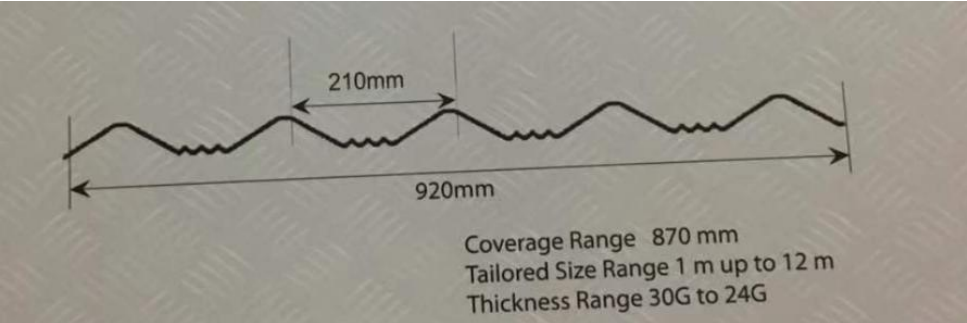

Here I will take the following drawing profile for your reference, actually all step tile design could be made to this type rolling forming machines.

Machine specialization:

Electric power: 11 kW-15 kW;Rolling speed: 8-12 m/min

Machine Weight: 10.0-14.0 tons

Dimensions (L x W x H): (9-12) m x 1.8 m x 1.8 m

Station quantity: 18-24 stations

Raw material: Steel Thickness: 0.2-0.8 mm (BMT)

Coil Width: 914-1450 mm

Material: GI, GL, PPGI, PPGL

Material Strength: G300-G550

Production specification

Control system: PLC, Touch Screen HMI

Rolling transmission: Servo motor

Cutting and pressing system

Hydraulic: Optional

Entrance shearer: Tolerance of steps ± 0.5 mm

Length Tolerance ± 2.0 mm

High speed step tile roofing sheet rolling forming machine design:

High speed step tile roofing sheet rolling forming machine working flow:

The machine is composed by the following elements.

| No. | Name | Unit | Quantity | Remark |

| Part 1 | 5 T decoiler | set | 1 | manual |

| Part 2 | Main roll forming machine

with stepping and shearing |

set | 1 | Chains drive |

| Part 3 | PLC control station | set | 1 | Delta brand |

| Part 4 | hydraulic system | set | 1 | YUKEN STANDARD |

| Part 5 | Product collect table | set | 1 | manual/3 m length |

Advantages of High speed step tile roofing sheet rolling forming machine:

1.The machine uses the gearbox as transmission for small noise and higher speed

2.As to the shearing and stepping pillar, we use the pillar frame, strong holding plate , one thing it can protect the cutting blade to use for a long time. Meanwhile it can make the machine looks more beautiful.

3.We design it with molding frame to make sure even if when working in high speed, the machine works still quite steady.

4.Leveling roller: the leveling roller and guiding rollers are moving with stainless material, by this way it will not damage the surface of the coil.

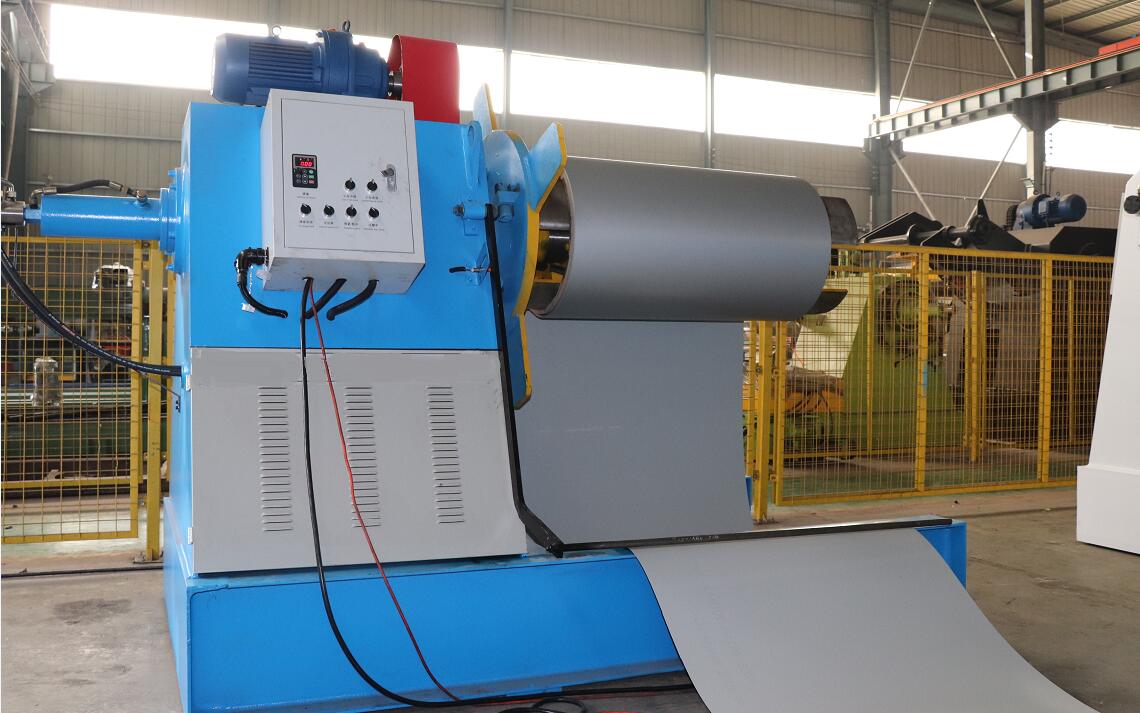

For the high speed step tile rolling forming machine, we had better choose the hydraulic decoiler, to higher speed like the following, 5 ton, 7 ton, 10 ton all okay. As to the loading car, you can choose to add or not.

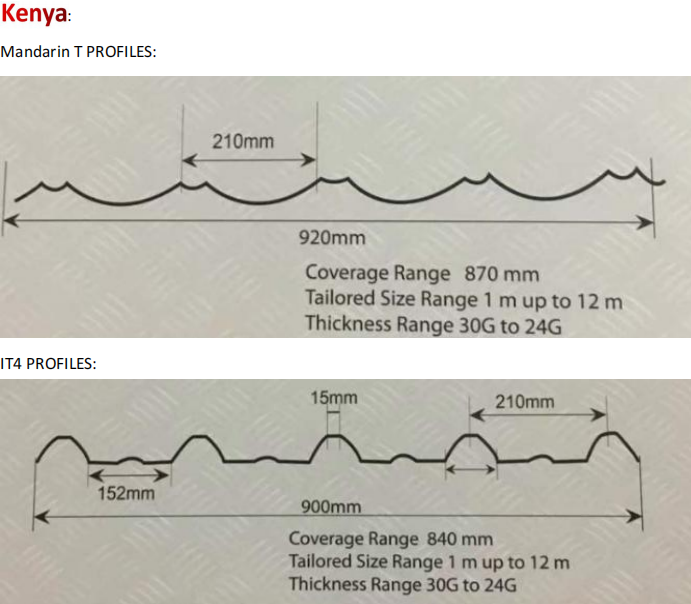

Here are more popular step tile drawing profile for your reference:

For this machine, if you want to know more information, please contact us at any time.