Standing Seam Roofing Sheet Machine - ZTRFM

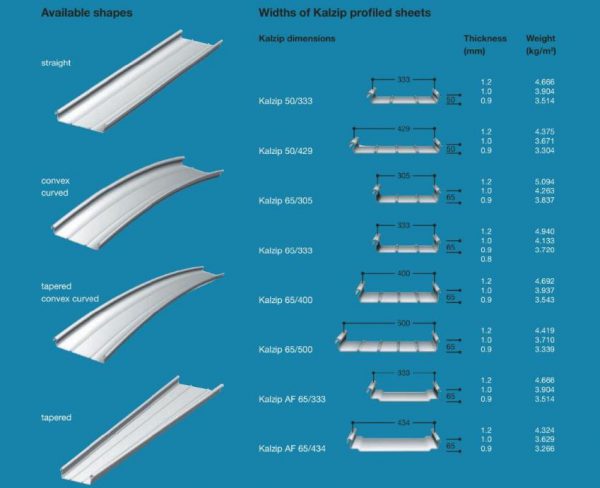

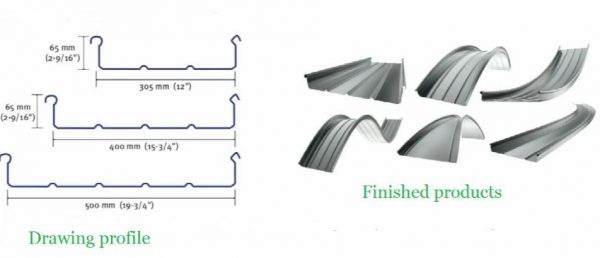

Standing Seam Roofing Sheet Machine is designed to make the standing seam in batch fully automatic by the rolling forming principle. This part we specially take the Bemo standing seam for example, Bemo type is designed by American company and now it is used all over the world as its good design and special function. The material could be like aluminium, steel,copper,stainless steel and titanium zinc etc, here I show the drawing profile for your reference:

Standing Seam Roofing Sheet Machine Parameter For your reference:

| No. | Main parameter | |

| 1 | Length of the main part | 7500 х 1650 х 1450 mm |

| 2 | Weight of main part | 6 Ton |

| 3 | Voltage | 380 V/ 50 HZ 3 Phase (as customer’s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | 350 H steel welded |

| 6 | Frame thickness | 18 mm thicker to be very strong |

| 7 | Drive mode | Chain of 1.25mm |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | Φ 70 mm |

| 11 | Number of rollers | 14rollers |

| 14 | Main power | 5.5kw |

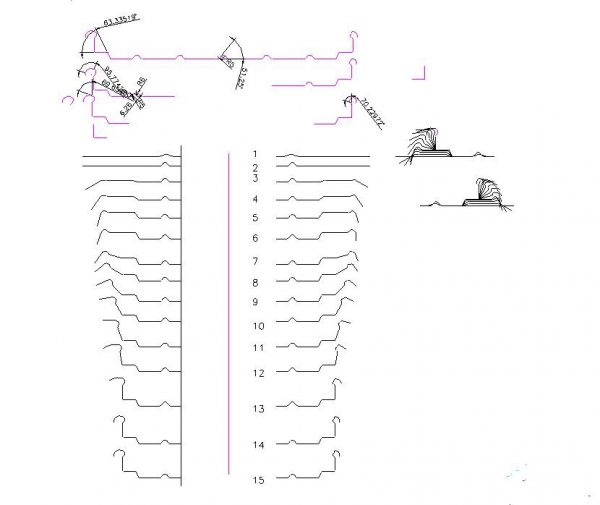

Bemo standing seam rolling process like this:

Standing Seam Roofing Sheet Machine design for your reference:

Advantages of this type Bemo style standing seam machine.

- One machine can make three or more types profiles.

- Side rollers are for two edge shape rolling.

- Speed can reach 15 to 25 meter per minute.

- Long time and easy to use.

- PLC control, cutting length could be controlled by PLC.

Bemo style standing seam machine Curving machine.